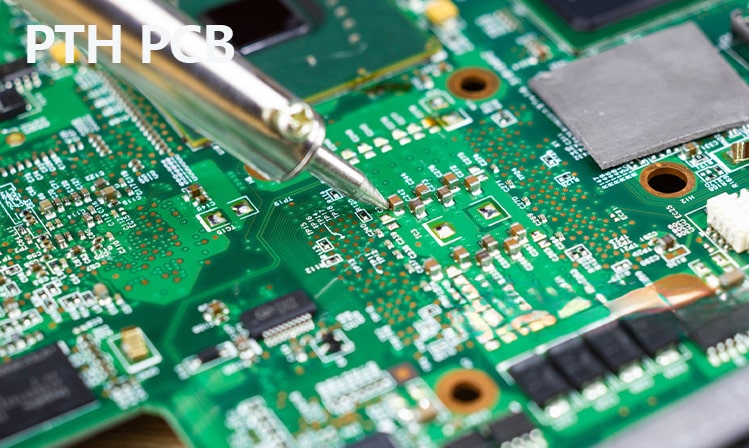

Plated Through Hole in PCB: Impact, Effect and Use

In modern electronic devices, printed circuit boards are an indispensable core component. The manufacturing process of PCB involves many key steps, among which the application of plated through hole (PTH) is crucial to the performance and reliability of PCB.

Plated through hole refers to the deposition of a layer of copper on the inner wall of the through hole on the PCB by chemical or electrochemical methods to form a metallized through hole. These through holes can be used for electrical connection or mechanical fixation.

Impact of plated through hole on PCB

Electrical performance: Plated through hole can provide stable electrical connection between different layers of PCB. By plating copper on the inner wall of the through hole, it can ensure that signals and power are reliably transmitted between layers, thereby improving the overall performance and efficiency of the circuit.

Mechanical strength: Plated through hole not only helps electrical connection, but also increases the mechanical strength of PCB. Copper-plated through holes are stronger than unplated through holes and can better withstand mechanical stress such as plugging and pulling and vibration.

Thermal management: Copper-plated through holes can also improve the thermal management performance of PCB. Copper has good thermal conductivity and can help dissipate heat, thereby improving the stability and life of electronic components.

The role of copper vias

Interlayer connection: In multi-layer PCBs, copper vias are the main way to achieve electrical connections between different layers. Through copper-plated through-holes, circuits can perform signal transmission and power distribution between different layers.

Component installation: Copper vias are also used to install components, such as through-hole components. The pins of these components are soldered to the PCB through copper vias to ensure stable mechanical and electrical connections.

Thermal conduction: In high-power applications, copper vias can be used as thermal vias to conduct heat from components to the heat dissipation layer or heat sink of the PCB to improve heat dissipation efficiency.

Uses of copper vias

Signal transmission: In high-speed signal transmission applications, copper vias can reduce signal loss, delay and interference, thereby ensuring signal integrity.

Power distribution: Through copper vias, power can be more evenly distributed to each layer of the PCB to ensure stable operation of the circuit.

Mechanical fixation: Copper vias are used to fix plug-in components and connectors, provide firm mechanical support, and prevent components from loosening or falling off.

Heat dissipation management: In high-power density circuits, copper vias help to quickly conduct heat to the heat dissipation layer and maintain the normal operating temperature of electronic components.

Copper vias are widely used in PCBs. They not only affect the electrical performance and mechanical strength of PCBs, but also play a key role in thermal management and component installation. Understanding the role and use of copper vias can better design and manufacture high-performance and high-reliability PCBs, providing a solid foundation for modern electronic devices.