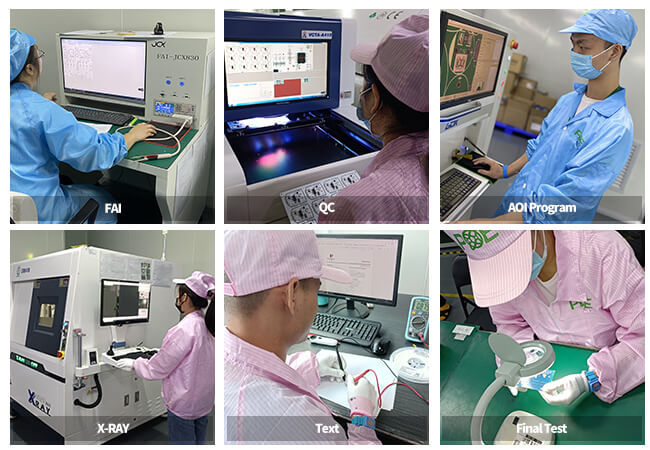

Quality Control

Quality Process

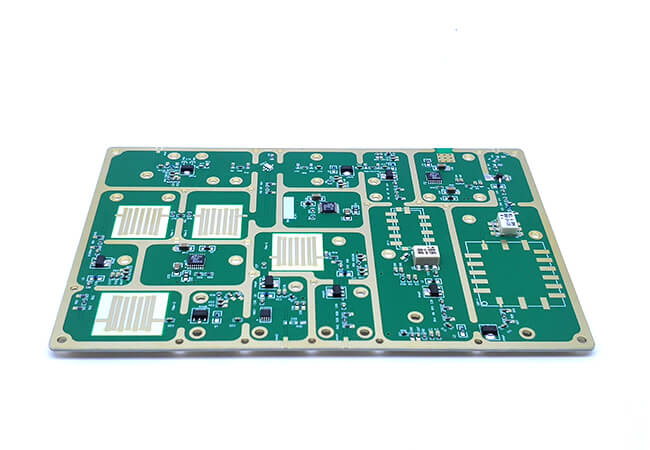

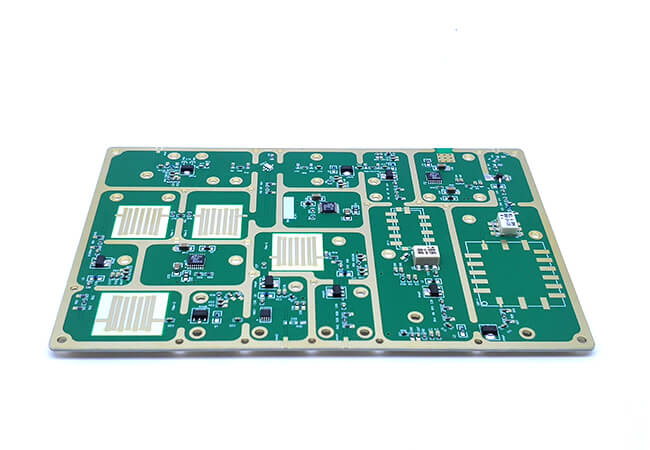

PCB is the heart of electronic equipment, and its quality and reliability are directly related to the quality and stability of electronic equipment. Nowadays, the intelligentization and miniaturization of electronic devices have led to smaller and smaller PCB sizes and more and more complex structures. In terms of PCB performance, even if the schematic design is correct, if the quality of the PCB design and manufacturing process is low, and the quality of the PCB is not inspected, the subsequent assembly and debugging will still be affected. Therefore, the quality control from PCB design to PCB manufacturing is particularly important.

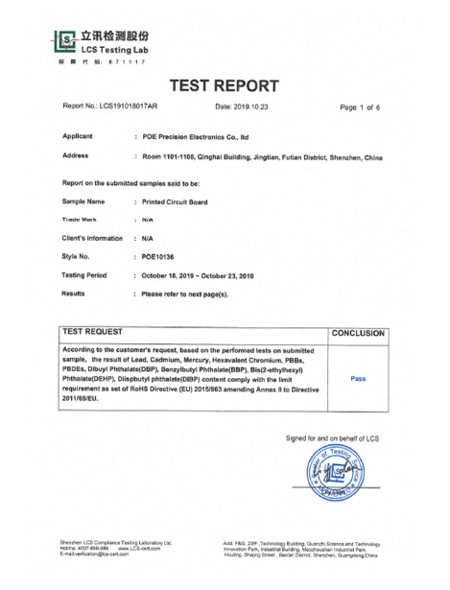

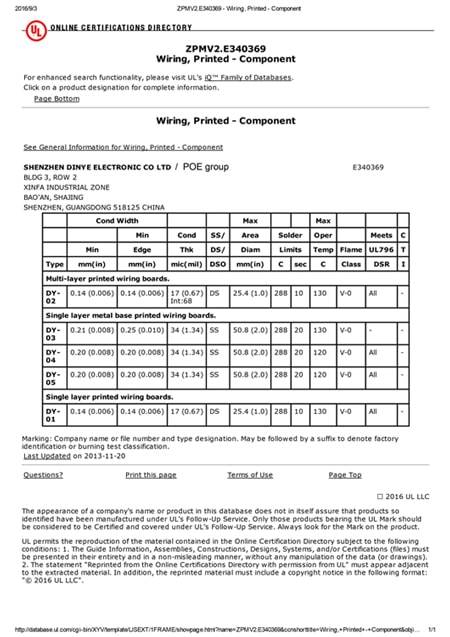

In order to satisfy customers, we have implemented the ISO9001 quality system. It has a complete quality assurance system and various testing equipment to monitor the entire production process to ensure the stability of the production process and the high quality of the products. At the same time, we have introduced advanced instruments and technical means to achieve continuous improvement.

Raw Material Control

With first-class brand raw materials guarantee the quality of the products.

Choosing the supplier of famous brand raw materials in PCB industry is the guarantee of stable quality of PCBAMake. We are committed to establishing long-term cooperative relationships with high-quality raw material suppliers, so that both sides can achieve mutual benefit and win-win.

IQC

First-class brand materials provide guarantee for the quality of the products.

Without the best materials any project will fail. That is why PCBAMake guarantees the first-class quality of raw materials. Our products refuse to compromise with unqualified raw materials.

Before purchasing raw materials, our professional quality inspection team will carefully check the quality of each item before delivery. Also, in addition to these routine inspection we will read all of your specifications carefully.

We insist on the quality of raw materials, perfect services and products, we will not be satisfied and excellent, ready to accept your strict requirement.

FQC

PCBAMake provides the best service and best products, I believe you have confidence in your products. We pride ourselves on our products, and we proud to say that our loyal customer base has a high proportion of re-investment. When your customers have been staying, you are doing the right thing.

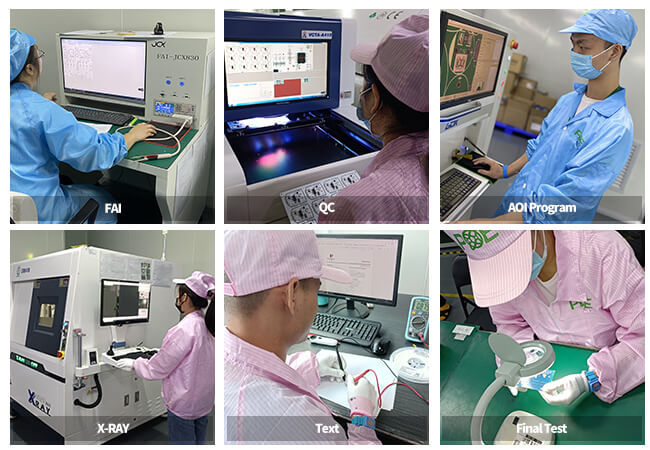

100% Final Inspection

The final inspection is the most critical of all inspections performed during the assembly process. This is the last opportunity to inspect and eliminate any problems on the assembled PCB before shipment. These include visual inspection, measurement of part characteristics, and response to low process capabilities. These can be done manually or in an automated process.

ESD Control

Dust-free anti-static workshop

5000 square meters of dust-free production workshop, the first layer of copper-clad, conductive layer, copper strip cylinder on the ground is 2.5 meters underground, to keep static electricity can be placed on the ground, anti-static workshop in line with certification standards.

High standard process

Anti-static detection and prevention process: release → whether the test is completed → if it exceeds the standard, it cannot be entered

Anti-static work clothes matching

Workers must wear anti-static clothes, anti-static shoes, anti-static caps, anti-static gloves, and anti-static bracelets when entering the workshop. PCBAMake strictly controls anti-static to ensure the life cycle of the product, which is truly assured and safe.

Controlled Impedance

Impedance is the sum of the resistance and reactance of an electrical circuit expressed in Ohms. The resistance being the opposition to current flow present in all materials. The reactance is the opposition to current flow resulting from the effect of the inherent capacitance and inductance of the conductor interacting with changes in voltage and current. In DC circuits there is no reactance and the resistance of copper conductors is typically insignificant.

However in high speed AC circuits (those with sharp changes in voltage and/or current) the reactance and thus the impedance can become very significant. This can become critical to a design's functionality because of the effects that changes in the impedance along the signals path from transmitter to receiver will have on the efficiency of power transfer as well as signal integrity. While a circuit’s speed is often expressed as the frequency of the wave form: the critical concern is the speed at which the voltage and/or current is required to change.