What is PCB Panelization

PCBAMake is a full service printed circuit board manufacturer providing industry leading technology in PCB Fabrication, PCB Assembly, components soucing, programming, funcation test, product assembly and so on.

Today we are gonna talk about the PCB Panelization.

1: What is PCB Panelization?

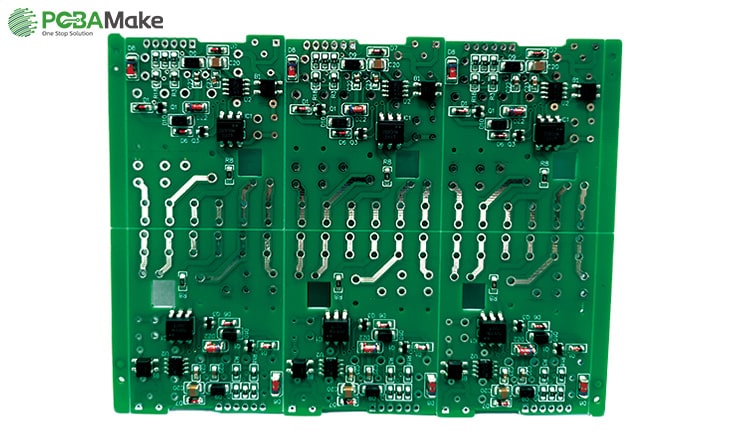

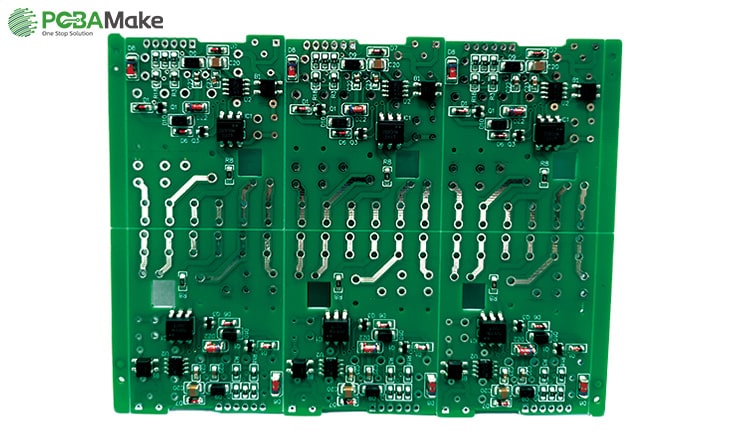

A PCB panel is an array of multiple individual printed circuit boards connected together to form a single, larger board. The most common case is to have panels with multiple copies of the same design, but in occasions different board designs can be combined into a single panel. The process of creating panels is called PCB panelization.

The board designer can create a panel in the PCB editor, or alternatively, the panel can be defined by the fabricator.

2: Why to use PCB Panels?

PCB assembly using automated equipment such as pick & place machines, stencil printers and reflow ovens provides higher efficiency than manual methods. It is a great option for prototype pcb assembly and low volume production, and the only viable option for high volume production. But automated PCB assembly imposes certain requirements that need to be met when designing and manufacturing a printed circuit board. An important part of these requirements is related to the PCB panel.

Yes, next we will talk about some of the most common reasons why PCB assembly factory will require you to panelize your PCBs:

When boards are small. Automated equipment has limitations in terms of the minimum board size they can handle. If the individual design is very tiny, this problem can be solved by creating a larger panel with appropriate dimensions

When quantity is high. By combining multiple printed circuit boards into a single panel, you increase efficiency as a larger number of boards can be processed at the same time. Hence, PCB panelization helps you save time and money, especially when dealing with large production volumes.

When components are too close to the edges. Since panels have rails, PCB panelization is a safer way to process boards than individual PCB assembly.

When ordering PCBs, you can submit your files in single format or panelized. If you send single board files, most PCB manufacturers can panelize your design at no extra cost.

3: Different Panel Types of PCB Assembly

V-cut

There is a V-cut slot between the boards cut with a V-cut machine, which can be easily broken when used. V-cut is suitable for the regular shaped PCBs with straight edges because the V-scoring machine will go through the whole board without stopping when running.

Tab-routing with breaking holes

PCB units with different sizes are also more suitable for Tab-routing. The edges of the two boards are connected by many small holes like stamp holes, which is easy to break.

Panel with both V-Cut and tab routes

For the consideration of PCB manufacturing, sometimes there need both V-scoring and tab-routing techniques on one panel as well.