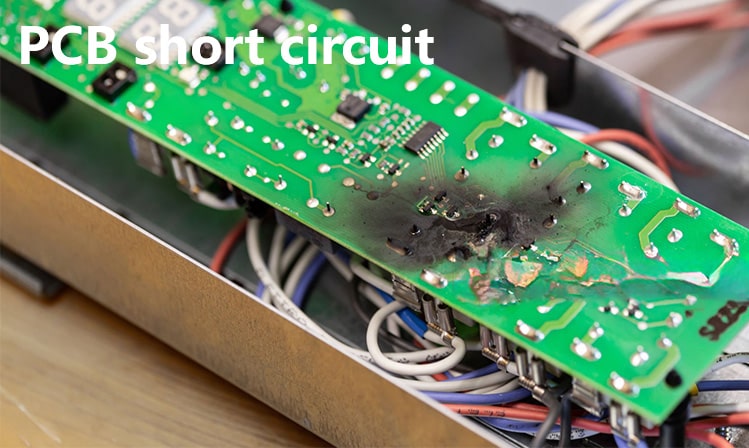

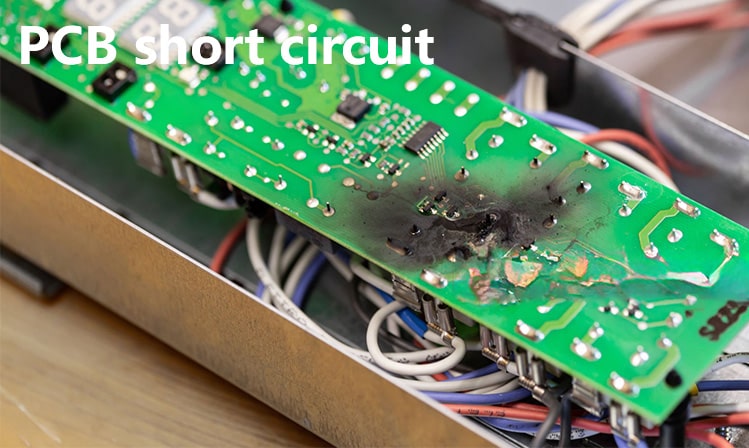

How to troubleshoot short circuits in PCBA processing

Methods to troubleshoot short circuits in PCBA processing. Troubleshooting short circuits in PCBA processing is a critical task that requires careful investigation and testing.

Methods to troubleshoot short circuits in PCBA processing:

1. Visual inspection: First, conduct a visual inspection to see if there is solder splashing on the circuit board, short circuits between wires between components, or between pads. Using a magnifying glass or microscope can help detect minor problems.

2. Thermal imaging detection: Use an infrared thermal imaging camera to detect temperature anomalies on the circuit board. Short circuits usually cause local temperature increases. This method is particularly useful for large circuit boards or dense component layouts.

3. Measure resistance: Use a multimeter to measure the resistance between various points on the circuit board. Under normal circumstances, there should be enough resistance between different circuits, while short circuits may cause the resistance to approach zero. Pay special attention to components or areas where short circuits may exist.

4. Use a short circuit detector: A short circuit detector is a tool specifically designed to detect short circuits in circuit boards. By moving the short circuit probe across the circuit board, a sound or light signal can be emitted to indicate potential short circuit points.

5. Break Detection: Use the continuity test function to check if the circuit is interrupted. Sometimes, a short circuit may be accompanied by a break, because soldering problems may cause some paths to be disconnected.

6. Component Replacement: If one or more problematic components are found, you can try to replace them and retest. Sometimes, there may be hidden problems in the components themselves that cause short circuits.

7. PCB Copy: If the short circuit problem cannot be located, you can consider copying the board, which means remaking a board with the same design and layout. If the problem persists, it may be a problem in the design or manufacturing process.

8. Professional Equipment: Some advanced test equipment, such as flying probe testers, can help locate short circuit problems on the circuit board.

When performing these tests and operations, be sure to operate carefully to avoid additional damage to the circuit board and components. If you still have difficulty in eliminating the short circuit problem, you may need to consider seeking help from a professional electronic engineer or testing service.

Measures to avoid short circuit failures

Optimize PCB design

During the design stage, layout components reasonably and avoid wires that are too close. Ensure that the design meets the manufacturing process requirements to reduce potential short circuit risks.

Improve welding quality

Use appropriate welding processes and materials to ensure welding quality and reduce the problems of excessive solder joints and solder residue.

Clean circuit boards

Ensure that circuit boards are kept clean and free from dust and pollutants during production and assembly. Clean equipment and work areas regularly.

Strictly control transportation and storage conditions

Ensure that circuit boards are free from moisture, high temperature and physical damage during transportation and storage.

Train employees regularly

Strengthen employee training to improve their awareness and handling of short-circuit faults and ensure that every link in the production process meets standards.

Short-circuit faults are common problems in PCBA processing, but the probability of their occurrence can be greatly reduced through reasonable detection methods and effective preventive measures. By continuously optimizing design, improving production processes and strengthening employee training, the reliability of electronic products will be significantly improved. If you need to know more about PCB proofing, SMT patch, and PCBA processing related technical knowledge, please leave a message to get it!