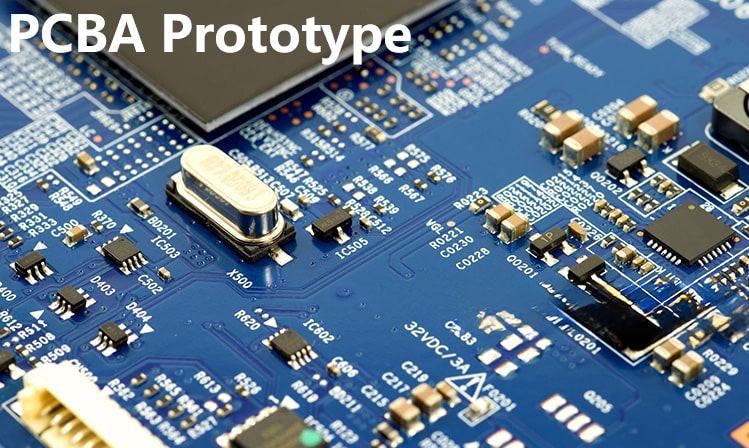

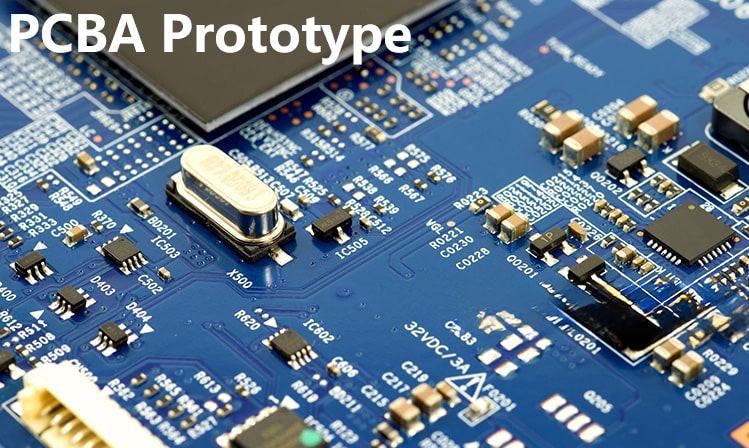

PCBA Prototype

What is a PCBA Prototype?

A PCBA prototype is an initial working model of the printed circuit board assembly. It allows designers and engineers to evaluate the PCBA design and make modifications as needed. Unlike the final product, prototypes are built in small quantities and often assembled by hand.

Prototyping serves several key functions:

1)Tests PCBA design functionality

2)Allows debugging and optimization before manufacturing

3)Reduces costs and development time

4)Validates manufacturing processes

5)Provides models for marketing and user testing

Well-executed prototyping is crucial for identifying and correcting issues early on, before they become expensive problems down the road.

Prototype Testing

Verifying a prototype's functionality, performance, and manufacturability is key.Common validation tests include:

1)Design - Confirm circuit design operates as intended

2)Functionality - Validate core feature and system-level functions

3)Interoperability - Test integration and connectivity with other hardware/systems

4)Environmental - Verify operation under expected environmental conditions

5)Compliance - Assess conformance with required standards and regulations

6)Reliability - Evaluate operation over time to pinpoint potential failure modes

7)Manufacturing - Assess assembly processes and production capabilities

8)Usability - Observe interaction by representative users to improve design

Determine the types of testing required to sufficiently validate your PCBA prototype, while keeping costs reasonable. Focus on high-risk or critical aspects of the design.

Finding a Reliable And Professional PCBA Partner

Here are tips for selecting a right PCBA partner:

1)Review their specific capabilities and expertise related to your project

2)Validate they can meet your quality, security, and confidentiality requirements

3)Examine lead times, location, and costs for budgeting

4)Evaluate their engineering support and design review services

5)Assess their prototyping experience, capacity, and certifications

6)Request customer references to confirm service reliability

Visiting a potential supplier’s facility allows thorough vetting of their operations.