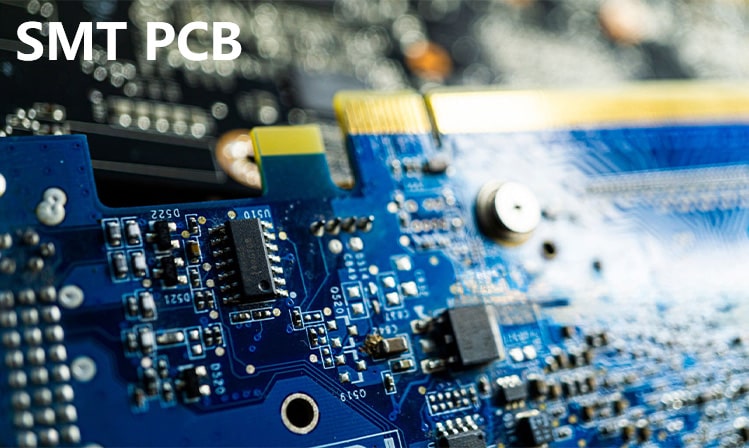

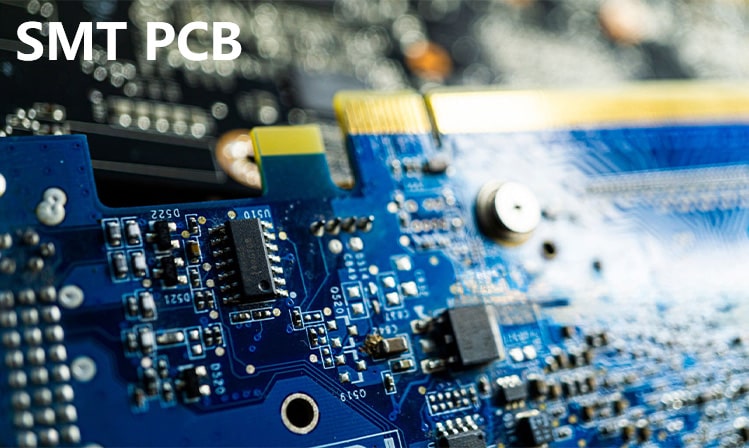

What are the obvious advantages of SMT processing plants?

SMT surface mount technology (Surface Mount Technology), as a key assembly technology in today's electronic product manufacturing industry, plays a vital role in modern industry. For the purchasing staff of electronic equipment manufacturers, it is crucial to have a deep understanding of the functions and advantages of SMT processing plants.

The main functions of SMT processing plants

SMT processing plants are mainly responsible for accurately mounting various electronic components on printed circuit boards (PCBs) through surface mount technology. This technology uses highly automated equipment to quickly and accurately place components on the specified position of the PCB, and then solder them through reflow soldering or wave soldering to finally form a complete circuit board assembly.

Generally, SMT processing plants provide a full range of services, including circuit board design, component procurement, patch processing, welding, testing, and subsequent assembly and packaging. This one-stop service model greatly saves customers' time and energy in supply chain management, production coordination and quality control, making the production of electronic products more efficient and convenient.

Advantages of SMT processing plants

1. High efficiency: SMT technology uses automated equipment, which greatly improves production efficiency and shortens the production cycle of products, thereby meeting market demand more quickly.

2. High quality: Due to the precise placement and welding technology, SMT processing plants can produce high-quality and high-reliability circuit board components, reducing quality problems caused by human factors.

3. Space saving: Surface mount components are small in size and light in weight, which can save space on the circuit board, which is conducive to the miniaturization and lightweight of electronic products, and meet consumers' demand for product appearance and portability.

4. Reduce costs: SMT technology can reduce manual operations and reduce production costs. At the same time, due to its high efficiency and high yield, it also helps to reduce overall production costs and improve the competitiveness of enterprises.

5. High flexibility: SMT processing plants can flexibly respond to different production needs. Whether it is small-scale trial production or large-scale production, they can provide efficient solutions and provide customized services to customers.

How to choose a high-quality SMT processing plant

1. Investigate technical strength: Understand the technical strength of the processing plant, the advanced level of equipment, and the maturity of the production process to ensure that it can meet your production needs.

2. Investigate the quality management system: A high-quality SMT processing plant should have a complete quality management system to ensure quality control in every production link and ensure the quality stability of the product.

3. Investigate delivery capabilities: Understand the production capacity, production cycle and delivery punctuality of the processing plant to ensure that it can deliver products on time and guarantee your production plan.

4. Investigate after-sales service: A high-quality SMT processing plant should provide comprehensive after-sales service, including technical support, maintenance services, etc., to ensure that the product can get timely support and help during use.

5. Investigate cost-effectiveness: In addition to price factors, it is also necessary to comprehensively consider the cost-effectiveness and service quality of the processing plant, and choose a processing plant that meets the budget and can provide high-quality services.

As a key link in the manufacturing of electronic products, SMT processing plants have the advantages of high efficiency, high quality, space saving, cost reduction and high flexibility, which makes them occupy an important position in the modern electronic manufacturing industry. Choosing a high-quality SMT processing plant will help improve product quality, reduce production costs and promote the sustainable development of enterprises.

If you want to know more, you can follow PCBAMake. If you need to know more about PCB proofing, SMT PCB patch, and PCBA processing related technical knowledge, please leave a message to get it!