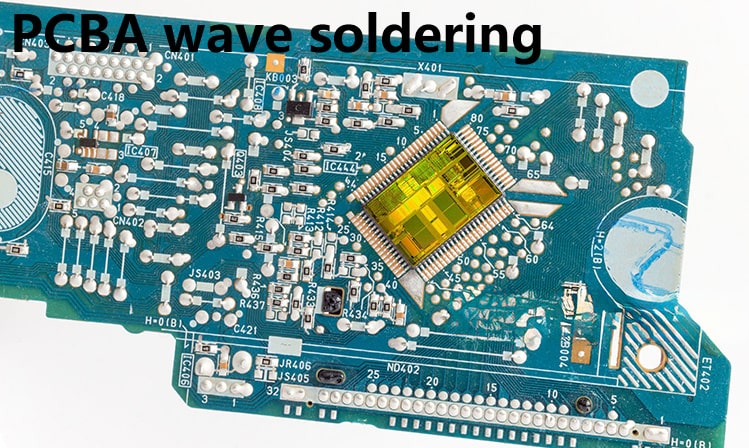

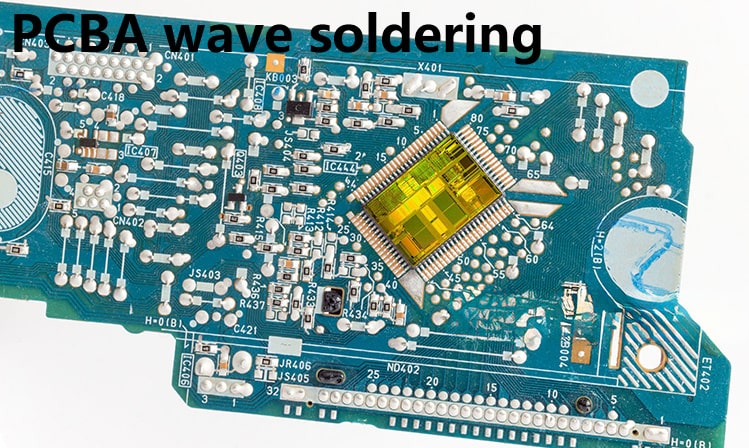

The purpose of preheating before PCBA wave soldering

For PCBA soldering process, a small detail may affect the quality and performance of the entire product. In the entire PCBA processing process, preheating is an extremely important step, especially in automated production and mass production. So, how important is preheating before PCBA soldering?

The purpose of preheating before PCBA wave soldering

First, preheating can effectively prevent the distortion and deformation of the PCBA board. During the entire PCB board production process, various reasons may cause the PCBA board to be subjected to certain deformation and stress, and these problems are likely to be further aggravated during the welding process. After introducing the preheating step, the stress inside the PCBA board can be completely released first, so as to ensure that distortion and deformation will not occur again during welding.

Secondly, preheating can enhance the wettability and fluidity of the PCBA board surface. Only when the PCB board surface is well wetted and the exposed pins of the IC are well bonded with the teardrops and circuit patches of the PCB board, can the welding achieve good results. By preheating, the temperature of the PCB board surface can be effectively increased, thereby enhancing the wettability and fluidity of the PCB board surface and achieving better welding results.

Again, preheating can improve the strength and corrosion resistance of the PCBA board surface. In the welding process, if there is a lack of preheating, it may cause structural relaxation and oxidation corrosion of the welding point. These problems may cause product damage and performance degradation after long-term use. Through proper preheating, the strength and corrosion resistance of the welding point can be effectively improved, and the quality of the product can be truly guaranteed.

In PCBA production and design, the preheating step cannot be ignored. It not only guarantees the quality of the product, but also plays a very critical role in improving PCBA production efficiency and reducing costs. If you want to improve the welding effect and reduce the product defect rate, you must pay attention to the preheating work before PCBA welding.

If you want to know more, you can pay attention to PCBAMake. If you need more technical knowledge about PCB manufacturing, SMT patches, and PCBA processing, please leave a message!