What are the reasons for the incomplete drilling during PCB processing

In today's society where electronic equipment is developing rapidly, PCBs serve as a connecting bridge between electronic components, and realize signal transmission and power distribution through precise wiring and drilling technology. If the bottom plate drilling is not drilled through, it is a common and special problem in the PCB manufacturing process.

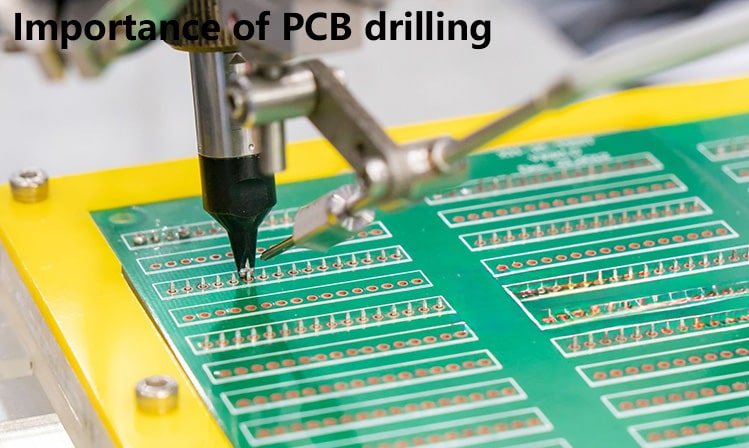

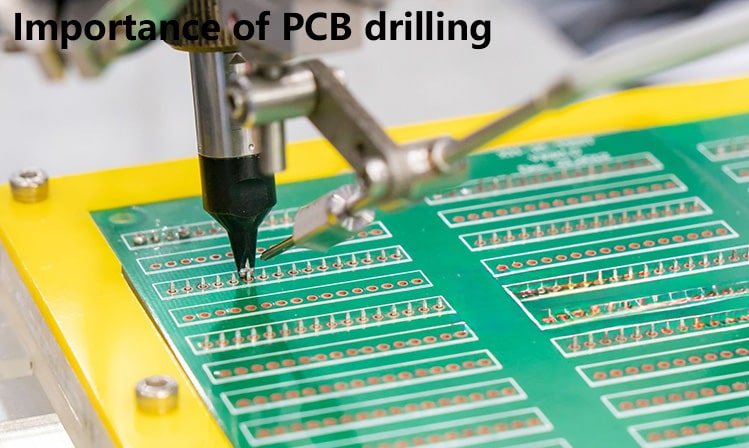

1. The importance of PCB drilling

PCB drilling is one of the key steps in the PCB manufacturing process. It is not only a via that penetrates the entire PCB board layer to form an electrical connection, but also a positioning hole and mechanical fixing hole for installing PCB components. Accurate and thorough drilling is essential to ensure the electrical performance of the circuit and the stability of the overall structure.

2. Possible factors for the failure of the bottom plate to be drilled through

1. Drill bit wear or damage

Wear: The drill bit will wear and become blunt after long-term use, affecting the drilling effect.

Damage: The drill bit may be damaged by hitting hard foreign objects (such as metal fragments mixed in the plate), resulting in the inability to penetrate the bottom layer.

2. Improper drilling parameter settings

Including unreasonable settings of parameters such as drilling speed, feed speed and drilling pressure, which may lead to incomplete drilling due to insufficient force or too fast.

3. Plate quality problems

Uneven thickness or density of different layers of materials in multilayer boards, as well as bubbles and impurities inside, will increase the difficulty of drilling and affect drilling penetration.

4. Positioning accuracy problems

If the positioning before drilling is not accurate enough, the drill bit may deviate from the predetermined trajectory, especially on thin boards or high-density boards.

5. Insufficient cooling and lubrication

Lack of sufficient coolant or lubrication during drilling will cause the drill bit to overheat, which will not only affect the drilling quality, but also may cause the drilling to fail.

III. Solutions

1. Regularly check and replace drill bits

Establish a strict drill bit management mechanism, regularly check the drill bit status and replace the severely worn drill bit in time to ensure drilling efficiency and quality.

2. Optimize drilling parameters

According to the material, thickness and hole size of the plate, reasonably adjust the drilling speed, feed speed and drilling pressure, and conduct tests to find the optimal parameter combination when necessary.

3. Improve raw material quality control

Choose suppliers with good reputation, strictly test the quality of the incoming plates, and avoid using defective materials.

4. Enhance positioning accuracy

Adopt advanced positioning systems, such as laser positioning or visual positioning technology, to ensure the accuracy of the drilling position.

5. Strengthen cooling and lubrication

Ensure sufficient supply of coolant or lubricant during drilling, effectively control the temperature of the drill bit, reduce wear, and improve the success rate of drilling.

6. Implement quality monitoring and feedback mechanism

Monitor the drilling process in real time, mark and reprocess the holes that are not drilled through immediately, collect data and feedback to the production management system, and continuously optimize the process flow.

Through these comprehensive measures, the incidence of PCB drilling bottom plate not being drilled through can be significantly reduced, the high quality and reliability of the circuit board can be ensured, and a solid foundation for the high performance of electronic products can be laid. In the highly competitive electronics manufacturing industry, precise attention to detail is what separates the good from the bad.