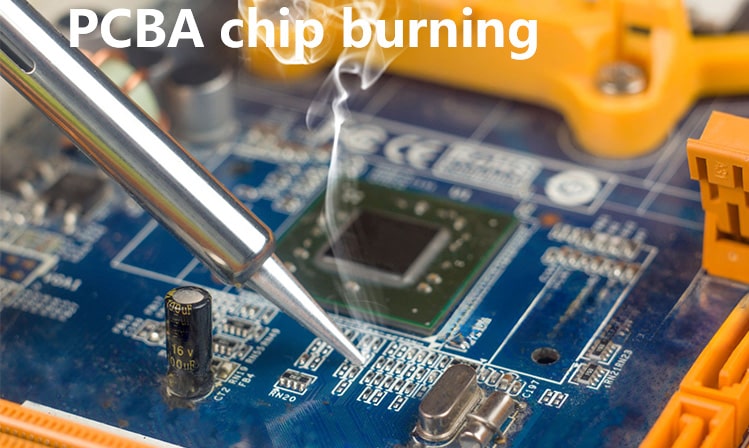

What is PCBA chip burning?

The importance of chip burning in PCBA processing

In the PCBA production process, "PCBA chip burning" is a very important link. It is directly related to the functional realization and performance of electronic products.

1. What is PCBA chip burning?

Chip programming simply refers to the process of writing specific software or firmware into the internal memory of the chip. The chip itself is usually blank, and the burning process writes the program or data required by the product into it to give it specific functions.

The goals of chip burning include: writing embedded software (such as MCU program), initializing configuration parameters, and loading test programs.

2. The basic process of PCBA chip burning

Chip burning usually requires the following equipment and steps:

1. Burning equipment

Programmer: a tool for writing code to the chip.

Test fixture: fixes the PCBA board and ensures the connection between the chip and the burner.

Burning software: software that controls the burning process, used to select program files and configure burning parameters.

2. Burning process

Prepare program files (Firmware): Developers write and test embedded software and generate binary files (such as .hex or .bin format) required for burning.

Connect the burner to PCBA: Connect the burner to the target chip on the PCBA through an interface (such as JTAG, SWD, UART or SPI).

Execute burning: Write the program file to the chip through the burning software and verify the correctness of the writing.

Functional test: After the burning is completed, the PCBA is tested to ensure that the program in the chip can work properly.

The importance of chip burning in PCBA processing

1. Realize chip functions

As the core component on the PCBA, the chip can only realize its function by burning firmware. For example, the microcontroller (MCU) needs to burn the program to control the operating logic on the circuit board; the storage chip needs to store data to operate normally.

2. Ensure product performance

The quality of chip burning directly affects the performance of the product. If the program is missing or an error occurs during the burning process, the entire PCBA may not work properly. Therefore, verification and testing after burning are particularly important.

3. Support customized needs

Different products have different functional requirements for chips. The burning process allows different firmware to be loaded according to the specific needs of customers, supporting product diversification.

4. Optimize production efficiency

In PCBA processing, automated burning equipment can greatly improve production efficiency. Through batch burning and automated verification, companies can quickly produce electronic products that meet the requirements.

5. Reduce the rework rate

By correctly burning and verifying the chip during the production process, product rework caused by program errors can be effectively avoided, thereby reducing production costs.

Future trends in PCBA chip burning

1. Automation and intelligence

With the intelligent development of the manufacturing industry, chip burning is gradually moving towards full automation. Modern automated burning equipment can complete burning and testing at the same time, greatly reducing manual intervention and improving production efficiency.

2. Remote burning

With the popularization of Internet of Things technology, remote burning technology has gradually emerged. Through the network, developers can directly burn new firmware into distributed devices to achieve remote updates and maintenance.

3. Enhanced security

The chip burning process involves the core code and data of the product, and the security requirements for the burning process will be higher in the future. For example, encryption technology is used to protect the firmware from being leaked or tampered with.

PCBA chip burning is a key step in the manufacturing of electronic products, which determines the functional realization of the chip and the overall performance of the product. With the advancement of technology, chip burning is moving towards a more efficient, smarter and safer direction. Mastering and optimizing chip burning technology is an important guarantee for improving competitiveness and product quality.