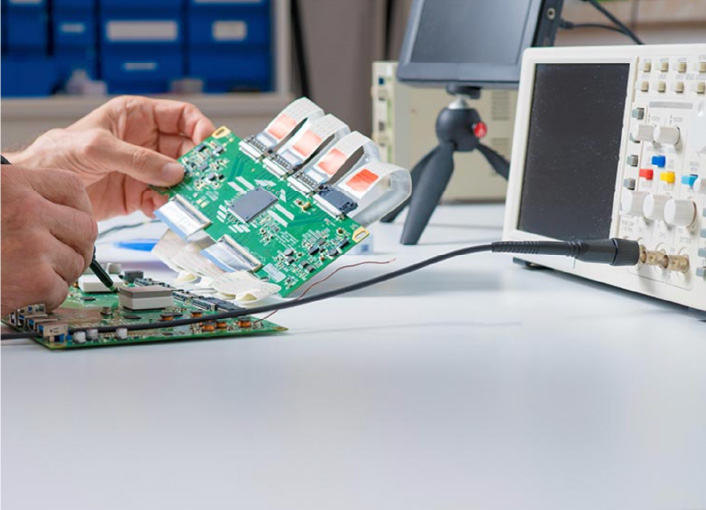

PCBAMake routinely works with end customers in a consulting capacity to ensure the board specs are the best fit for the end application and within budget. We are PCB experts and this is one way that we differentiate ourselves from brokers in this industry. We know PCBs and are passionate about working with our customers to impact their competitiveness, time to market, R&D on new products and more.

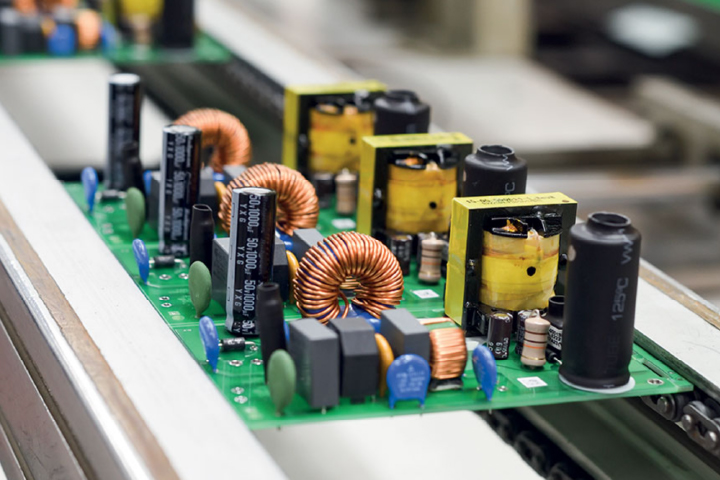

Value-added Service

PCBAMake has always strived to offer its customers value-added services. We treat our customers’ needs as our own needs. Since we have learned tremendously through working experiences with multi-national companies from the USA, Australia, and European countries, PCBAMake has formed its own management philosophy based on the integration of their sophisticated management style.

We will always learn from the others, adopt 5S, Lean Manufacturing and Six Sigma quality systems combining with state-of-the-art equipment for continuous improvement within the entire operation of EMS service.