There are a lot of problems that can affect the global PCBA manufacturing and supply chain. The recent COVID-19 pandemic is the most obvious example of this. There are however other events that can also cause problems for the supply chain, such as:

Materials shortages: Another reason for part shortages is if the component manufacturers can’t get enough raw materials to meet their production quotas.

Political disturbances: These problems can affect everything from manufacturing to shipping, and they will result in higher than expected prices or reduced production.

Coronavirus: With the restrictions imposed in many countries to combat the recent outbreak of the Coronavirus, manufacturing plants have seen their workforce diminished. New social distancing requirements require workers to be more spread out, while other employees are unable to work due to family conflicts or being sick themselves. In many cases, manufacturing plants were shut down entirely, which further damaged the supply chain.

Whatever the cause, fluctuations in your supply chain can impact your product delivery, including:

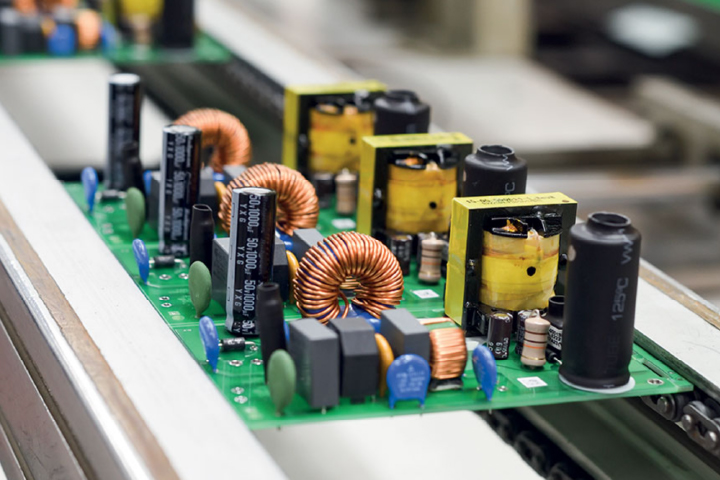

- Component shortages for building circuit boards.

- Materials used in the manufacturing of circuit boards are not readily available.

- Communication breakdowns between you and overseas manufacturers.

- Labor shortages in the areas of the problems that affect your manufacturers.

- Fluctuating prices that cause your board production to be over-budget.

- Shipping problems that delay you from getting the product back into your factories.

Thankfully, there are people with an understanding of these different supply chain dynamics that can help.