What is the standard for the thickness of the three-proof paint for PCBA processing

Standard specification for the thickness of the three-proof paint

One-stop PCBA intelligent manufacturing manufacturer will tell you today what is the standard for the thickness of the three-proof paint for PCBA processing? Standard specification for the thickness of the three-proof paint. The thickness standard of the three-proof paint coating can vary according to different specific usage requirements and material types. Generally speaking, the thickness of the paint film is recommended to be controlled at 20~30 microns, the thickness of the primer is generally required to be 15~20 microns, the thickness of the intermediate paint is generally required to be 10~15 microns, and the thickness of the topcoat is generally required to be 5~10 microns.

At the same time, the conditions and requirements of the three-proof paint are generally 0.15~0.35mm, the spraying environment should be carried out in a dry and dust-free environment, the room temperature should be controlled between 15℃~30℃, and the relative humidity should be maintained at 40%~60%. In addition, in order to ensure the thickness of products with high protection requirements, a secondary coating can be performed after the paint film is cured (determine whether to perform a secondary coating based on demand).

Please note that these are only general reference standards. The specific thickness standards should be determined according to the actual situation. Different process requirements and material properties will affect the thickness. Therefore, in actual applications, the requirements of the product manufacturer should be referred to, and the appropriate coating thickness should be determined in combination with the specific use environment and conditions.

Standard specifications for the coating thickness of three-conformal paint:

1. Technical indicators

Film thickness: The film thickness of the three-conformal paint after spraying should meet the requirements of the product manufacturer, usually controlled between 0.1mm and 0.3mm. The specific thickness standard may vary due to different usage requirements and material types.

Adhesion: The three-conformal paint should have good adhesion to the substrate after spraying to meet the use requirements of electronic products in harsh environments.

Hardness: The hardness of the three-conformal paint after spraying should meet the specified requirements to ensure the product's scratch resistance during transportation and operation.

Corrosion resistance: The three-conformal paint should have excellent corrosion resistance after spraying, and can effectively resist the erosion of various chemicals.

2. Construction requirements

Spraying environment: Conformal coating spraying should be carried out in a dry and dust-free environment. The room temperature should be controlled between 15℃ and 30℃, and the relative humidity should be maintained at 40% to 60%.

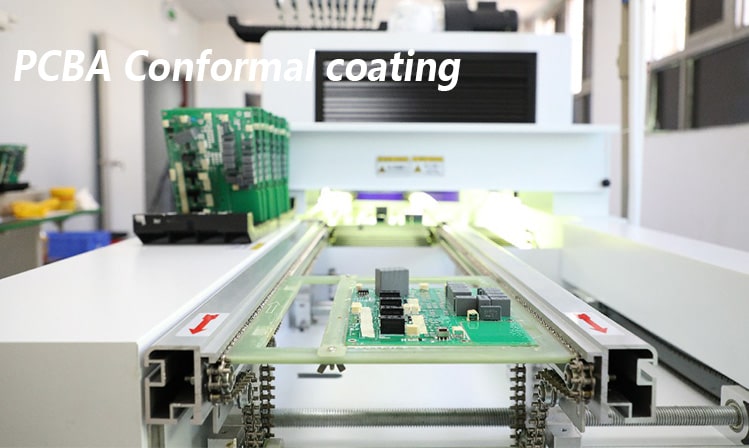

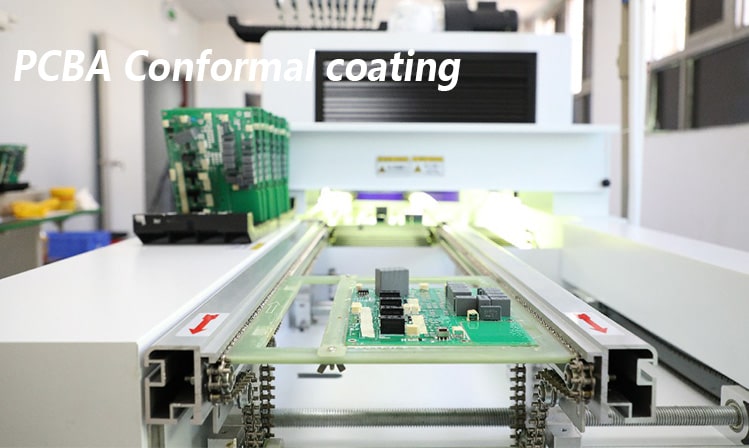

Spraying equipment: Conformal coating spraying equipment should use appropriate spray guns, spray chambers, air supply systems, etc. to ensure safety and environmental protection during the spraying process.

Spraying operation: PCB Conformal coating spraying operation should strictly follow the process flow and parameters provided by the product manufacturer to ensure the quality and effect of spraying. At the same time, pay attention to controlling the amount of paint sprayed to avoid too thick or too thin coating.

3. Quality inspection

Visual inspection: After the conformal coating is sprayed, the appearance quality of the coating, such as flatness, glossiness, and leveling, should be checked by visual inspection.

Thickness measurement: Use appropriate measuring tools (such as coating thickness gauges) to measure the thickness of the paint film to ensure that it meets the specified standards.

It should be noted that the specific conformal coating thickness standard specifications may vary due to different industry standards, product characteristics and use environments. Therefore, in practical applications, relevant industry standards, product manufacturer requirements and specific usage conditions should be referred to determine the appropriate coating thickness to ensure optimal product quality and performance.

Follow PCBAMake. If you need to learn about PCB proofing, SMT patching, and PCBA processing related technical knowledge, please leave a message to get it!