Which PCB need to be coated with conformal coating?

Types of PCB circuits that need to be coated with conformal coating

In the electronics industry, PCB circuit boards, as the basic components of electronic equipment, carry the vital tasks of circuit connection and component installation. However, since PCB circuit boards are often threatened by various external factors, such as moisture, dust, corrosive gases, etc., some PCB circuit boards need to be coated with conformal coating to improve their reliability and service life.

Types of PCB circuits that need to be coated with conformal coating

1. PCB circuit boards in the field of industrial controlIndustrial control equipment usually needs to operate for a long time under harsh environmental conditions, such as factory workshops, field operations, etc. In such an environment, PCB circuit boards are easily corroded by moisture, dust, chemicals, etc., so conformal coating is required to protect their stability and reliability.

2. PCB circuit boards in the military field

The military field has extremely high requirements for the reliability of electronic equipment, because these devices often need to be used in harsh battlefield environments. Coating with conformal coating can protect PCB circuit boards from the influence of water, dust, chemicals, etc., ensuring that the equipment can operate stably under various extreme conditions.

3. PCB circuit boards in the field of automotive electronics

Automotive electronic equipment often needs to face harsh environments such as humidity, high temperature, and vibration, so PCB circuit boards are easily damaged. In order to improve the reliability of automotive electronic equipment, coating three-conformal paint is an indispensable measure.

4. PCB circuit boards in the field of aerospace

Aerospace equipment needs to operate under extreme temperature, humidity, and air pressure conditions, so the stability and reliability of PCB circuit boards are crucial. By coating three-conformal paint, PCB circuit boards can be effectively protected from the influence of the external environment to ensure the normal operation of aerospace equipment.

5. PCB circuit boards in the field of medical electronics

Medical equipment has extremely high requirements for reliability and stability, because these devices are usually used for life-saving and diagnosis, and once a failure occurs, it may have a serious impact on patients. Coating three-conformal paint can protect PCB circuit boards from erosion by liquids, chemicals, etc., ensuring the normal operation of medical equipment.

PCB circuit boards that need to be coated with three-conformal paint usually include equipment in the fields of industrial control, military industry, automotive electronics, aerospace, and medical electronics. These devices usually need to operate for a long time under harsh environmental conditions, so the PCB circuit boards need to be protected to ensure the reliability and stability of the equipment. By applying conformal coating, PCB circuit boards can be effectively prevented from being corroded by moisture, dust, chemicals, etc., extending their service life, reducing failure rates, and improving the overall performance of the equipment.

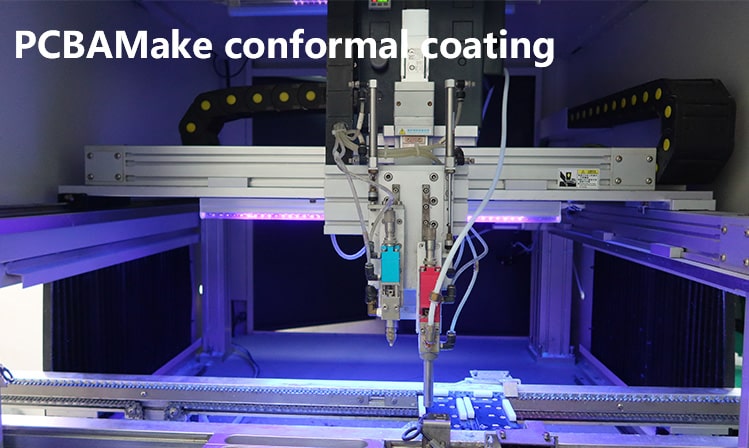

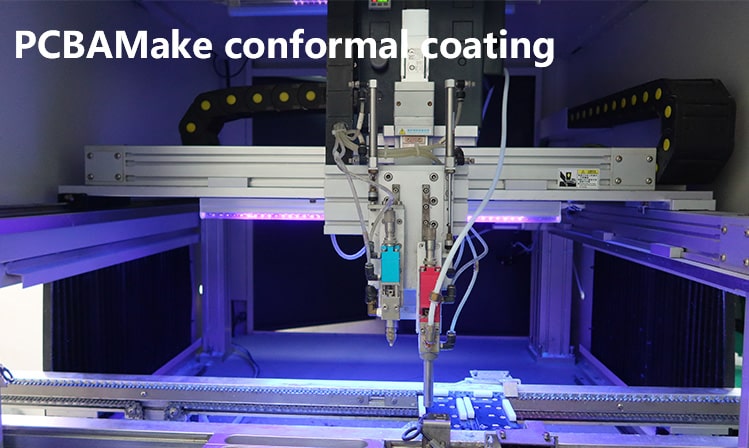

Application methods of conformal coating

The application methods of pcb conformal coating include spraying, brushing, and dipping. Choosing the right method depends on the scale of production, the shape of the equipment, and the degree of protection required.

As the application scope of electronic devices continues to expand, conformal coating is becoming increasingly important in protecting PCBs from environmental damage. Choosing the right conformal coating and application method can significantly improve the performance and reliability of the equipment. Whether it is outdoor equipment operating in extreme climates or industrial and automotive electronics used in harsh conditions, conformal coating is an indispensable protective barrier.

PCBAMake has professional conformal coating production lines and rich experience in PCBA SMT processing. If you have related needs, please feel free to contact us. We look forward to providing you with quality services to ensure that your electronic devices perform well in various environments.