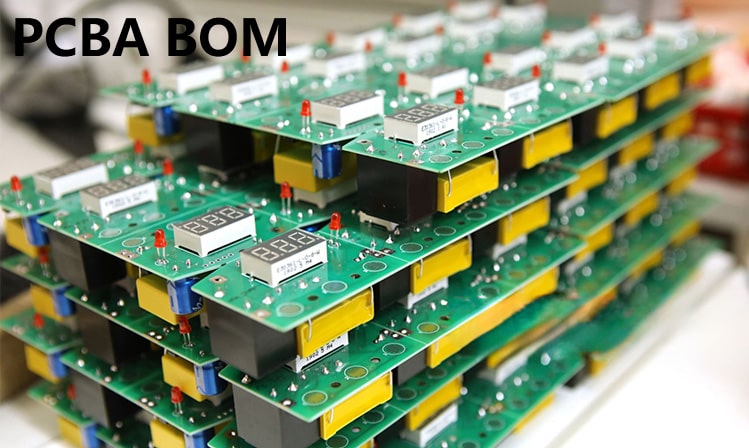

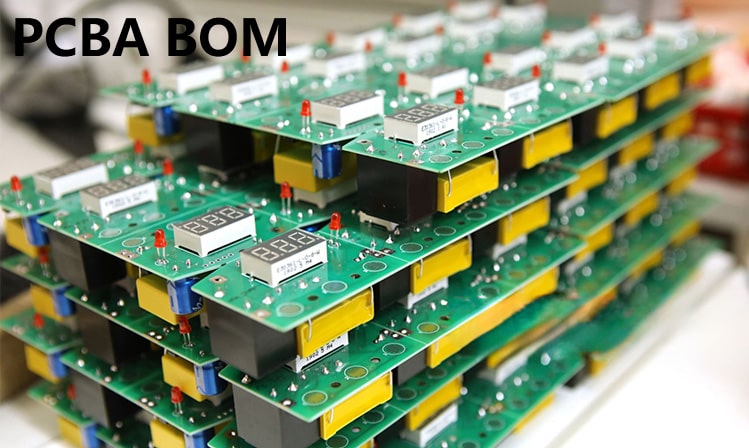

Why is BOM so important in PCBA processing?

BOM plays a key role in PCBA processing. It is a detailed list of all components and materials used on PCBA, including the name, model, quantity, supplier information, etc. It is an indispensable part of the entire production assembly process and has a direct impact on product quality and production efficiency.

BOM is important for all aspects of PCBA processing:

Component procurement: BOM provides manufacturers with detailed information about each component that needs to be purchased, including component model, quantity, supplier information, etc. This helps ensure that procurement personnel can accurately obtain the required parts and avoid material shortages or wrong procurement.

Production planning: BOM provides the information required by assembly engineers to determine the steps and sequence of the assembly process. It can help determine which components are placed on the PCB at what time to ensure the correct order of assembly.

Quality control: BOM provides the specifications and quality standards of each component, which helps quality control personnel to check and verify the quality of each component during the production process. This helps ensure that the final PCBA has a consistent quality level.

Cost Control: The BOM also includes cost information for each component, which helps manufacturers estimate the cost of production and conduct cost control. Manufacturers can develop cost budgets and optimize production costs based on the cost information in the BOM.

Maintenance and Repair: The BOM is also very important for maintaining and repairing PCBAs. It provides detailed information on each component, including model and reference information, which helps maintenance personnel locate and replace faulty components more easily when needed.

Change Management: If changes or upgrades to the PCBA are required, the BOM can serve as a basic document for recording and managing any changes or revisions. This helps track and maintain different versions of the PCBA.

In short, the BOM is a key reference document in PCBA service processing, which ensures transparency, quality control, cost control, and change management of the production process. It is the foundation of PCBA manufacturing and helps ensure that the production process is efficient and reliable and produces high-quality PCBAs.