Take you into the PCB aluminum substrate

The pcb aluminum substrate is what we often call the aluminum-based circuit board, referred to as the aluminum substrate, which is a metal-based copper clad laminate with good thermal conductivity, electrical insulation properties and mechanical processing properties. At this stage, the common aluminum PCB china substrate material is metal-based copper clad laminate (mainly aluminum-based and copper-based, and a small part is iron-based).

Metal aluminum-based copper clad laminate is a type of plate-like material made of electronic fiberglass cloth or other reinforced materials impregnated with resin, singulation resin, etc. as the insulating adhesive layer, one or both sides covered with copper foil and hot pressed. , Mainly used for processing and manufacturing aluminum PCB substrates, which are commonly used in televisions, radios, computers, computers, mobile communications, LED lighting and other products.

Advantages of aluminum PCB substrate

1. The heat dissipation is significantly better than the standard FR-4 structure.

2. The dielectric used is usually 5 to 10 times the thermal conductivity of traditional epoxy glass and 1/10 of the thickness.

3. The heat transfer index is more effective than traditional rigid PCB.

4. You can use copper weights lower than those shown in the IPC recommended chart.

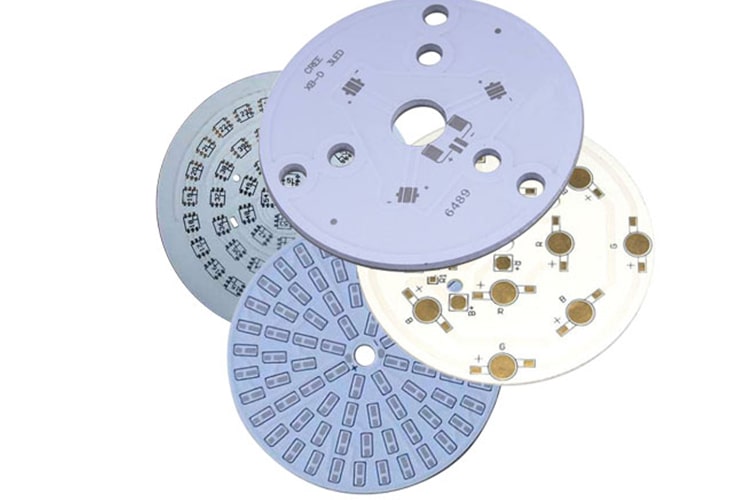

Types of aluminum substrates

Aluminum substrate is a metal-based copper clad laminate with good heat dissipation function

1. Flexible aluminum substrate

With excellent electrical insulation, flexibility and thermal conductivity, it can be formed into products to achieve various shapes and angles, and eliminate expensive fixing devices, cables and connectors.

2. Mixed aluminum substrate

A 2-layer or 4-layer component made of traditional FR-4, and then bonded to an aluminum substrate with a thermoelectric dielectric, helps to dissipate heat, improve rigidity, and act as a shield.

3. Multilayer aluminum substrate

It is made of multiple layers of thermally conductive dielectric, with one or more layers of circuits embedded in the dielectric, and blind holes are used as thermal vias or signal paths.

4. Through-hole aluminum substrate

Before lamination, aluminum is electroplated and filled with dielectric in advance. Thermal materials or sub-components can be laminated to both sides of the aluminum using thermal adhesive materials. Once laminated, the finished assembly resembles a traditional multilayer aluminum substrate, with plated through holes passing through gaps in the aluminum to maintain electrical insulation.

As the substrate material in the production of aluminum PCB substrates, metal aluminum-based copper clad laminates are mainly used for connection, conduction, insulation and support for PCB aluminum substrates, and have great effects on the transmission speed, energy loss and characteristic impedance of the signal in the line. Interference. The performance, quality, processability in production, manufacturing level, manufacturing cost and long-term reliability and stability of pcb aluminum substrates are basically determined by metal aluminum-based copper clad laminates.

In PCB production, aluminum substrates are special plates, which have certain technical thresholds and difficulty in operation, and the cost is also high. Therefore, it is very important to find a professional and suitable circuit board manufacturer. POE is a professional PCB assembly manufacturer, you can contact us at any time if you have any needs, we will complete each PCB board with quality and quantity!