Why do flexible PCBs need to be introduced

PCB board stiffener

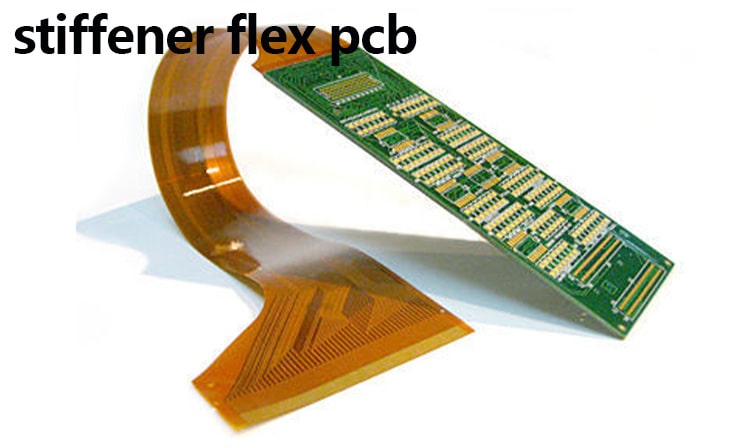

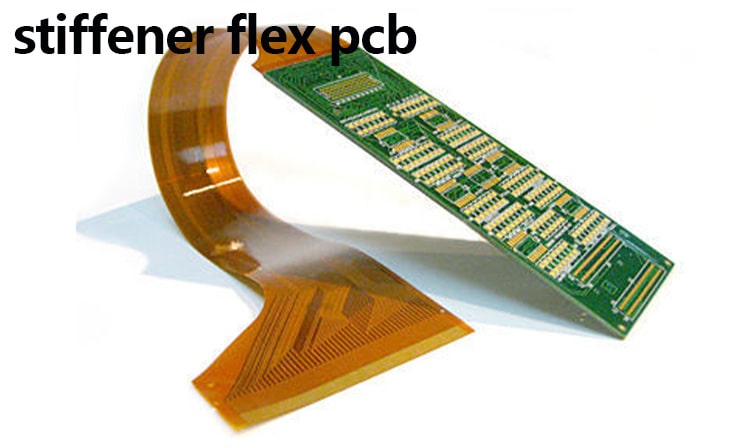

Flexible printed circuit boards (FPCBs) are widely used in various electronic devices because of their thinness and flexibility. However, due to these characteristics, flexible PCBs may encounter problems such as insufficient mechanical strength and easy bending and deformation in some applications. In order to solve these problems, the introduction of PCB board stiffener has become a common design method.

What are PCB board stiffener?

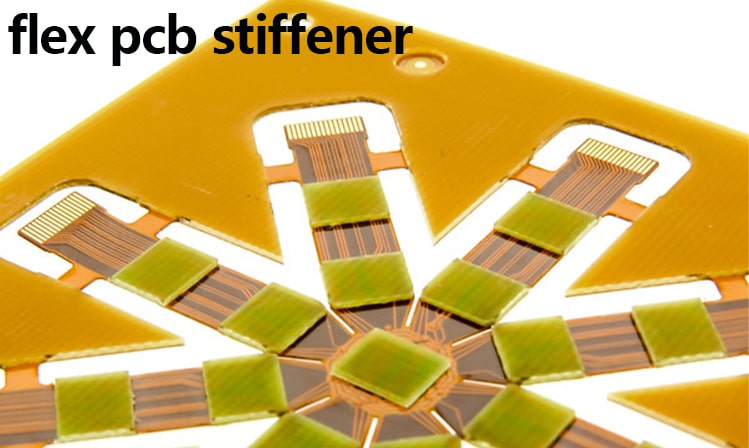

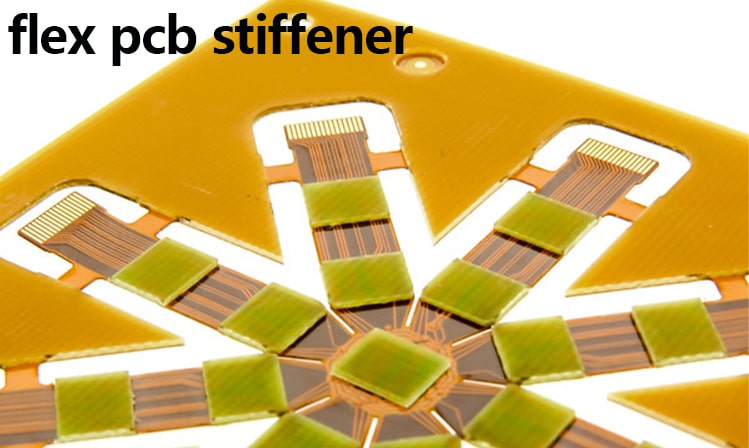

Stiffeners are a hard material attached to flexible PCBs, usually made of polyimide (PI) or glass fiber reinforced resin (FR4). They are fixed to specific areas of the PCB by hot pressing or bonding to enhance its mechanical strength and stability.

The role of PCB board stiffener

Enhance mechanical strength: Flexible PCBs may be subjected to mechanical stresses such as bending and stretching during installation and use, and are prone to deformation or damage. Stiffeners can provide additional support to prevent PCBs from being damaged during these processes.

Improve connection stability: Adding stiffeners near connectors or soldering points can avoid poor connections or breaks in these key areas due to excessive bending.

Improve assembly process: Flexible PCB may need to be folded and unfolded many times during the assembly process. Ribs can help maintain its original shape, simplify the assembly process and improve production efficiency.

Heat dissipation management: In some high-power applications, ribs can also act as heat sinks to help disperse and manage heat to avoid performance degradation or failure caused by overheating.

Other PCBs that require ribs

In addition to flexible PCBs, other types of PCBs may also need to use ribs, mainly including the following:

Rigid-Flex PCB: This type of PCB combines the advantages of rigid boards and flexible boards. Ribs are often used at the joints between rigid and flexible parts to provide additional mechanical support and protection.

Multi-layer flexible boards: Multi-layer flexible boards have complex structures and are easily affected by mechanical stress during manufacturing and use. Ribs can improve their overall mechanical strength and reliability.

High-frequency and high-speed circuit boards: These circuit boards usually require a very stable structure to ensure the reliability of signal transmission. Ribs can provide the necessary mechanical support and reduce signal interference.

PCB stiffener materials and selection

Common PCB stiffener materials include:

Polyimide (PI): This material has excellent heat resistance and mechanical strength and is often used in demanding applications.

Fiberglass reinforced resin (FR4): FR4 is a common PCB substrate with good mechanical properties and cost-effectiveness.

Metal sheets: such as stainless steel or aluminum, are mainly used in applications that require high strength and thermal conductivity.

PCB board stiffener play a key role in flexible PCBs and other PCBs that require additional mechanical support. Stiffeners can not only enhance the mechanical strength of the PCB, improve connection stability, and simplify the assembly process, but also play a role in heat management in some applications. Choosing the right stiffener material and design can significantly improve the performance and reliability of the PCB. By making rational use of stiffeners, engineers can better cope with various challenges in the design and manufacturing process to ensure the quality and performance of the product.