The difference between reflow soldering and wave soldering

Reflow soldering

On the SMT (surface mount) production line, pcb reflow soldering and pcb wave soldering are two key soldering processes. Although both involve the use of solder, their working principles and applicable scenarios are different.

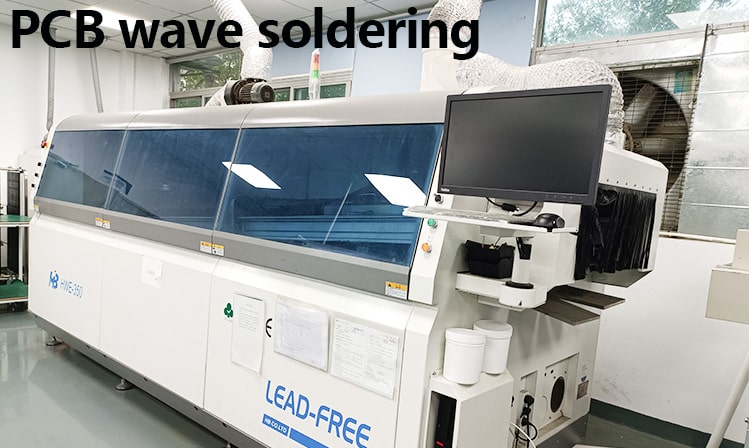

First, let's take a look at pcb reflow soldering. It uses the principle of hot air convection to make the surface mount components on the PCB board electrically connected to the solder joints. During the reflow soldering process, the PCB board enters the soldering furnace heating area through a conveyor belt, and undergoes preheating, insulation and cooling stages in turn to ensure that the solder paste is fully melted and forms a stable and reliable connection between the component pins and the PCB pads.

PCB Reflow soldering technology is particularly suitable for the soldering of SMD (surface mount devices). The pins of these components are designed to be very short and can fit closely with the surface of the PCB board.

Wave soldering

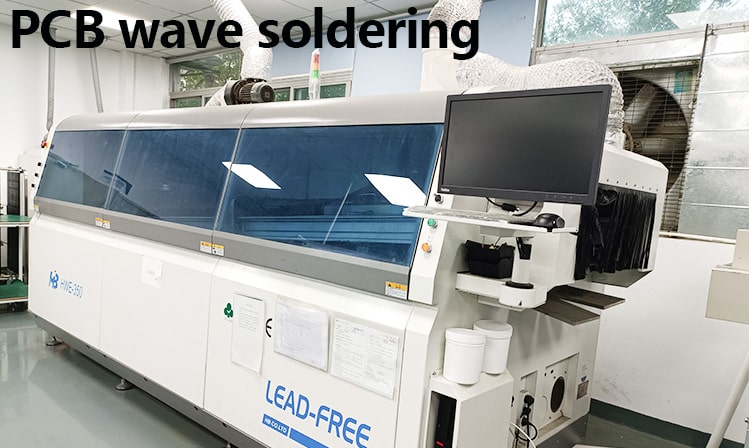

The working principle of PCB wave soldering is based on the formation of continuous waves by molten liquid solder. During the wave soldering process, the circuit board is transported through the conveyor belt of the wave soldering furnace. When the pins of the circuit board pass through the liquid solder wave, they come into contact with the solder, which adheres to the pins and then solidifies during the cooling process to form a solid electrical connection.

PCB Wave soldering is particularly suitable for the soldering of plug-in electronic components. These components usually have long pins and need to be inserted through holes in the PCB board and soldered on the other side by wave soldering technology.

The difference between reflow soldering and wave soldering

First, in terms of equipment, PCB reflow soldering equipment is usually more complex, containing multiple heating zones and cooling zones, while wave soldering equipment is relatively simple, mainly containing a solder wave.

Secondly, in terms of soldering objects, PCB reflow soldering is mainly used for soldering surface mount components (SMD), while wave soldering is more suitable for soldering through-hole components (THT).

The above are the main differences between PCB wave soldering and PCB reflow soldering. I hope today's content can bring you some gains!