- Home

- About us

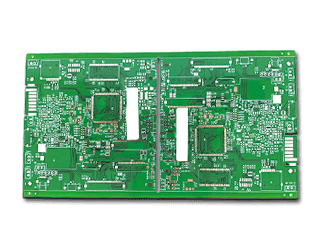

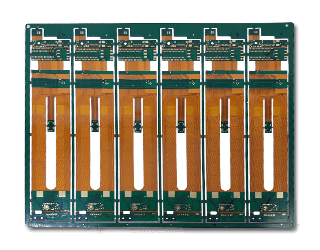

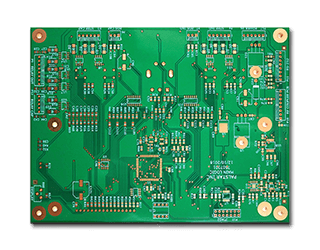

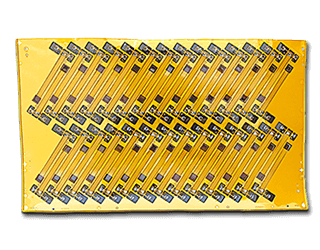

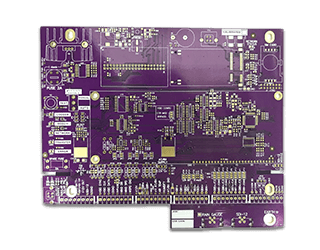

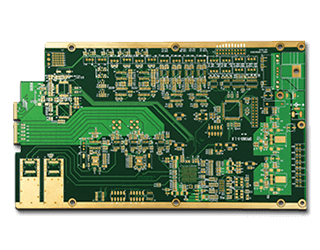

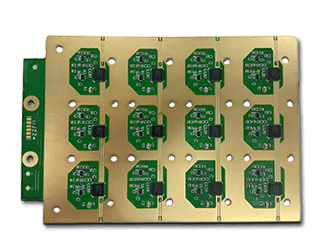

- Products

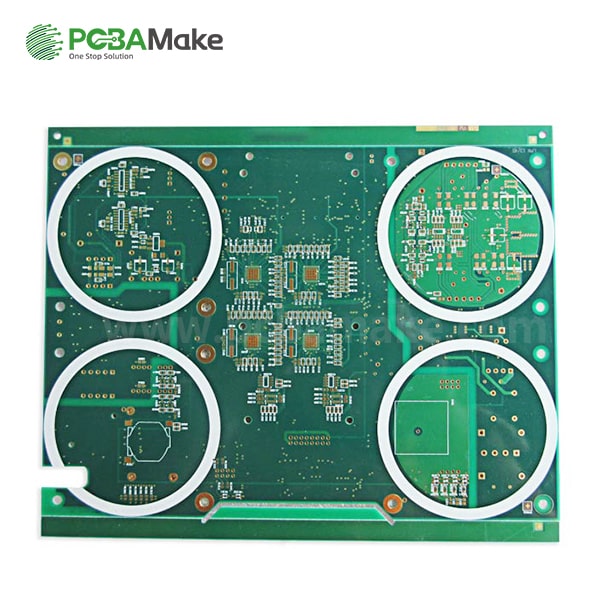

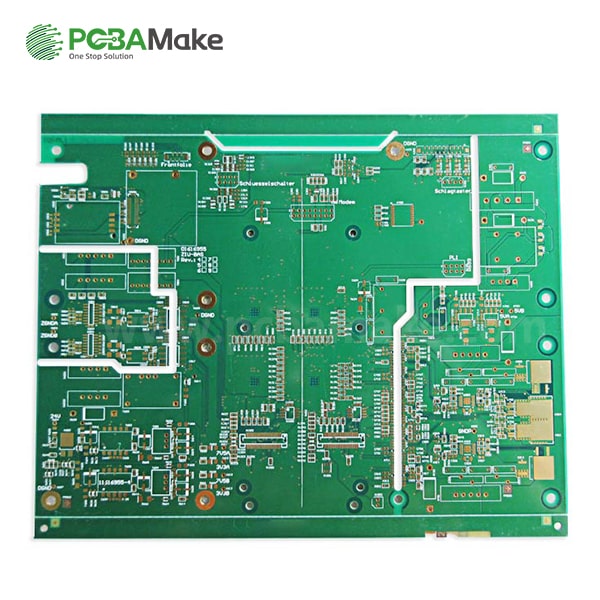

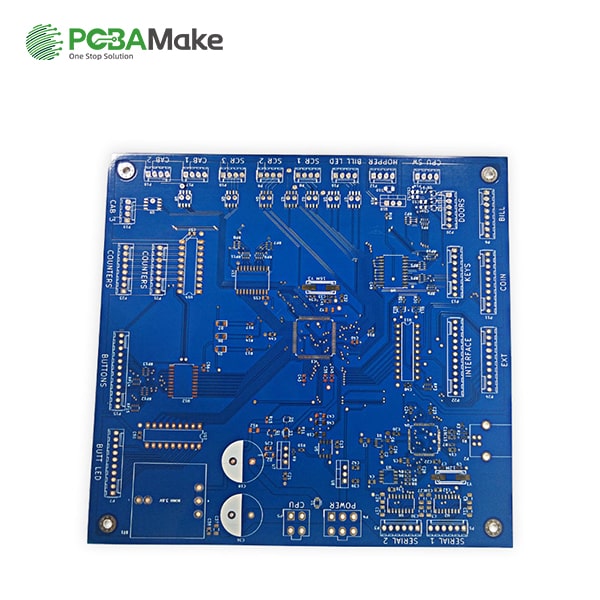

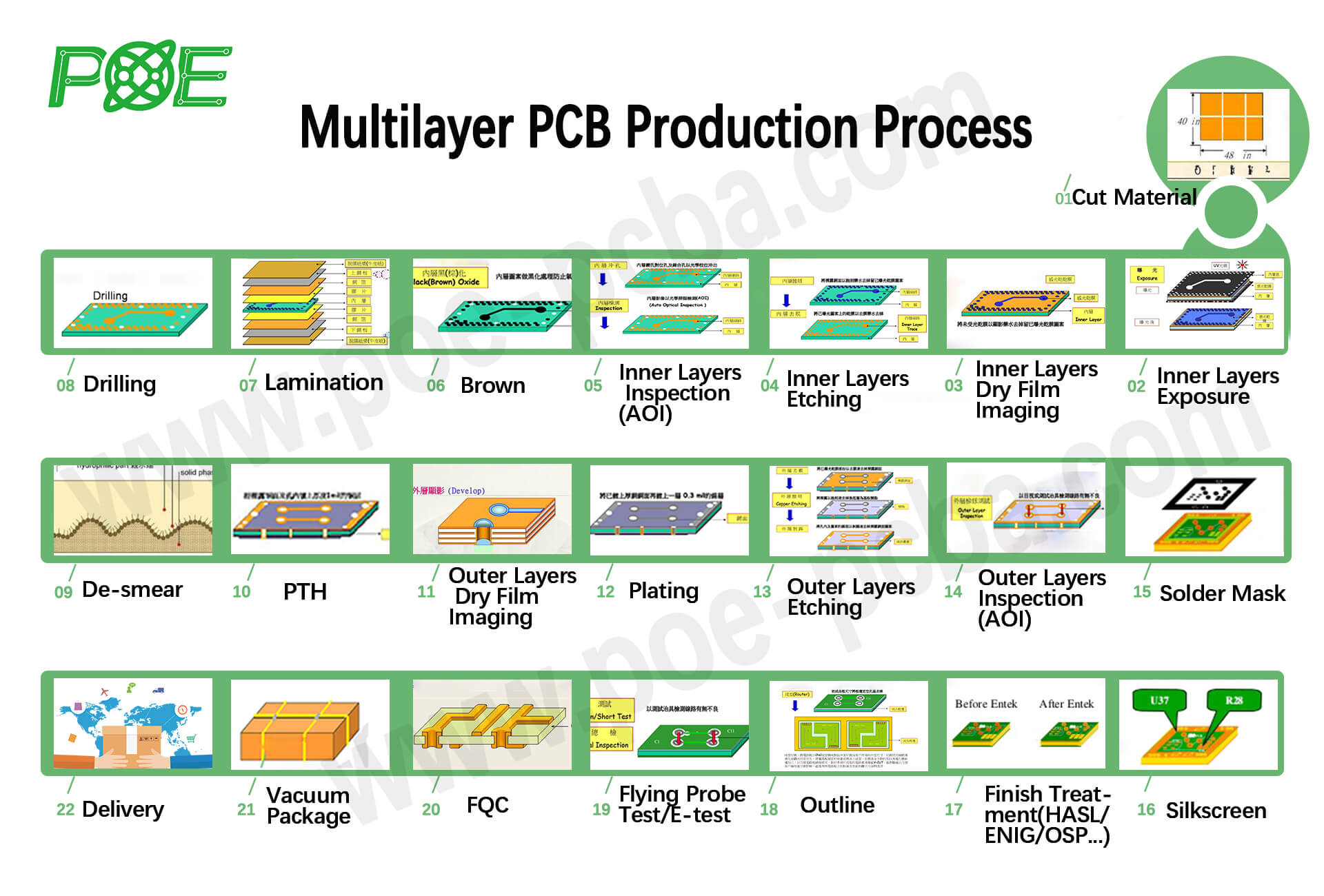

- PCB Fabrication

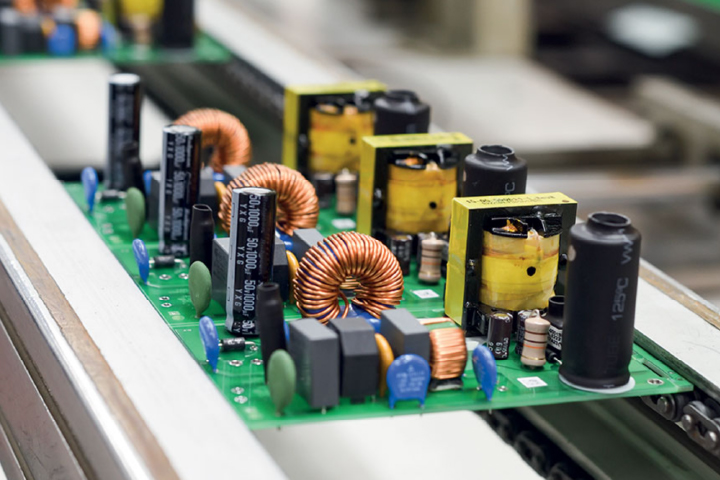

- PCB Assembly&OEM

- Solutions

- Quality

- Blogs

- Contact

One-Stop Turnkey PCB Assembly Manufacturer

Company Profile

Company Profile, Advantage,Mainly Products & Industries, Marketing Distribution

Milestone

Company History,Events

Culture

Company Mission,Vision, Team Culture

Award & Honor

Awards, Honor,Certificate

Social Responsibility

Environmentally Protect,Health and safety Plicy

News

Company News, Exhibition News,Industry News

Customer Service

Customer Service

One-Stop Turnkey PCB Assembly Manufacturer

One-Stop Turnkey PCB Assembly Manufacturer

One-Stop Turnkey PCB Assembly Manufacturer