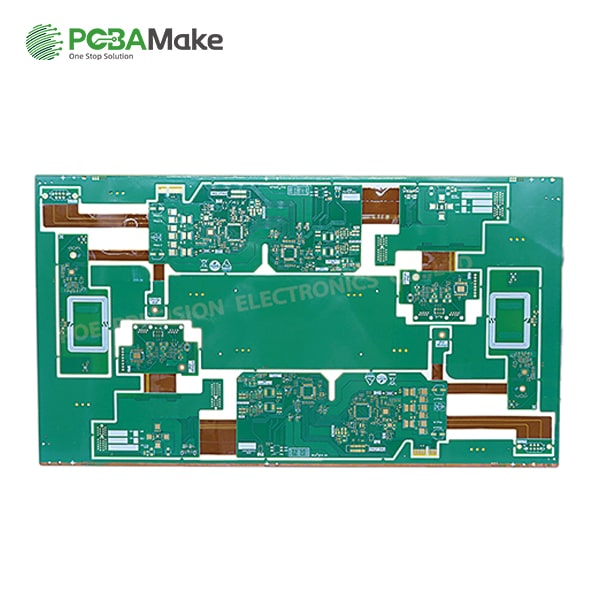

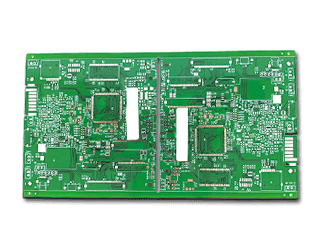

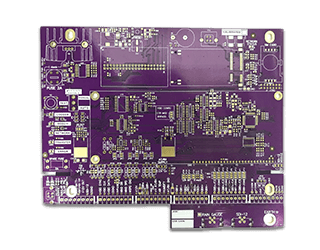

Rigid-flex PCB

The birth and development of FPC and PCB gave birth to the new product of Rigid-flex PCB board

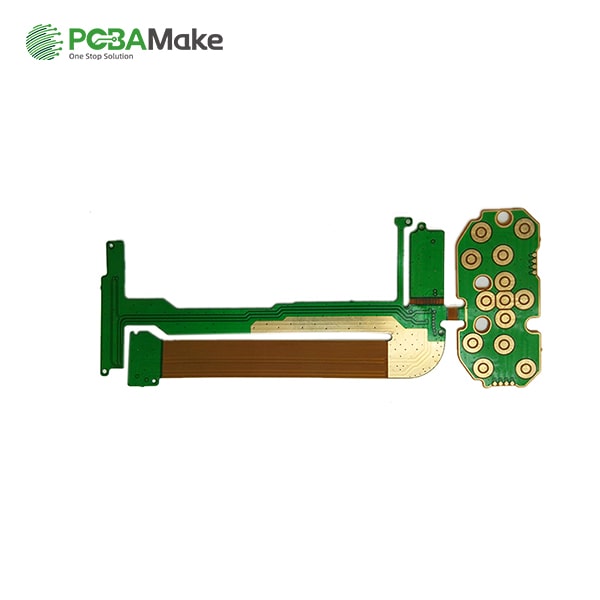

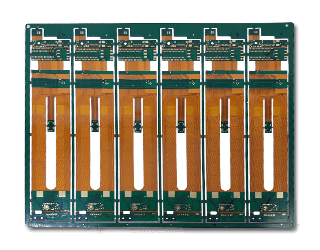

Rigid-flex PCB is a circuit board with FPC characteristics and PCB characteristics formed by combining flexible pcb circuit boards and rigid pcb circuit boards according to relevant process requirements through lamination and other processes.

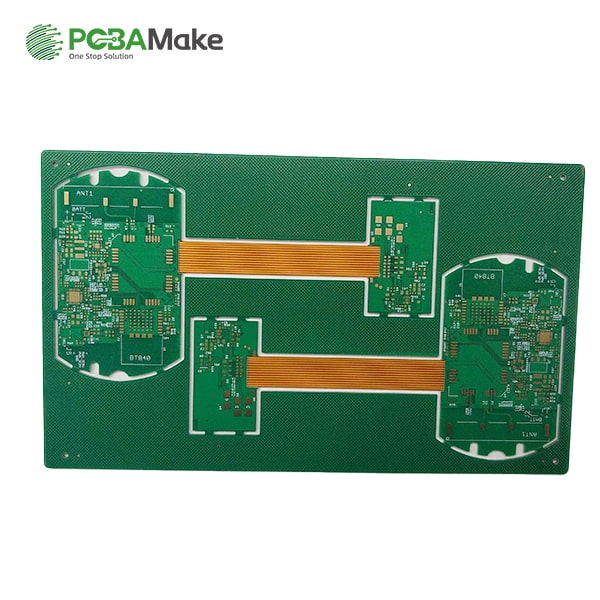

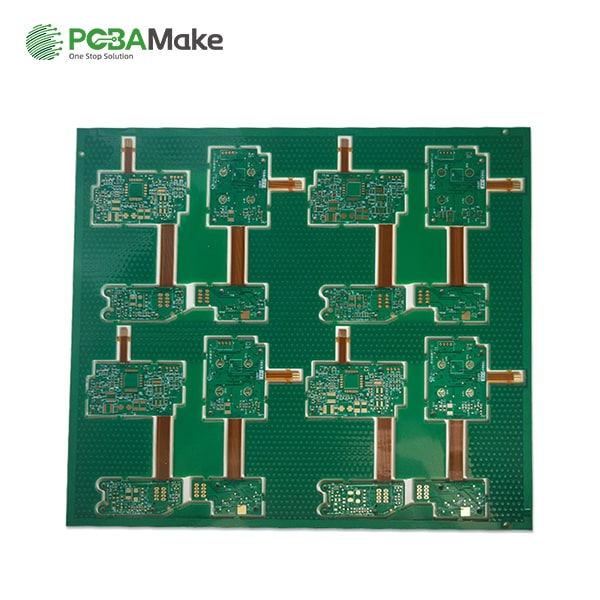

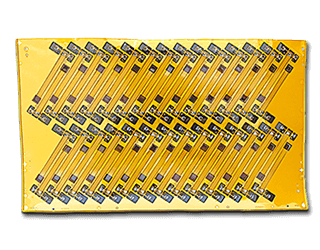

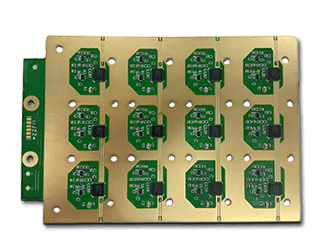

Rigid-flex PCB is a special flexible printed circuit board composed of rigid-flex and flexible substrates selectively laminated together, with a tight structure and electrical connections formed by metallized holes. It has the characteristics of high density, thin wire, small aperture, small size, light weight and high reliability, and its performance is still very stable under vibration, shock and wet environment. Flexible, three-dimensional installation, effective use of installation space, is widely used in mobile phones, digital cameras, digital video cameras and other portable digital products. Rigid-flex PCB boards will be used more in areas where packaging is reduced, especially in consumer areas.

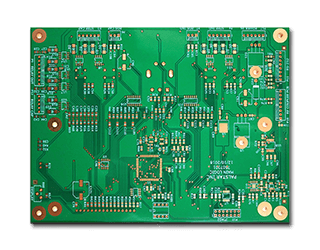

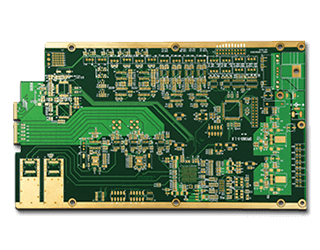

Rigid-Flex PCB Manufacturing Applications

Rigid-flex PCBs offer a wide range of applications from smart devices to mobile phones and digital cameras. Rigid-flex pcb manufacturing has been increasingly used in medical devices such as pacemakers to reduce their space and weight. The use of rigid-flex PCBs has the same advantages and can be applied to intelligent control systems.

In consumer products, flex-rigid PCB boards not only maximize space usage and minimize weight, but also greatly improve reliability, eliminating many of the need for soldered joints and fragile, fragile wiring that is prone to connection problems. These are just a few examples, but rigid-flex PCBs can benefit nearly all advanced electrical applications, including test equipment, tools, and automobiles.