UAV & Drone PCBA:

The UAV(Unmanned Aerial Vehicle) have managed to come a long way in a very short time, all because of advanced printed circuit boards. The UAV as with Space/Satellites and Avionics, small devices require low weight and offer minimal space to design on.

PCB solution is often a Rigid-Flex to be able to avoid space demanding contacts and keep the weight down. Also Some UAV PCBs even need to be able to perform in outer space and must be extremely durable. Boards made with lightweight materials such as aluminum are also beneficial for use in aerospace.

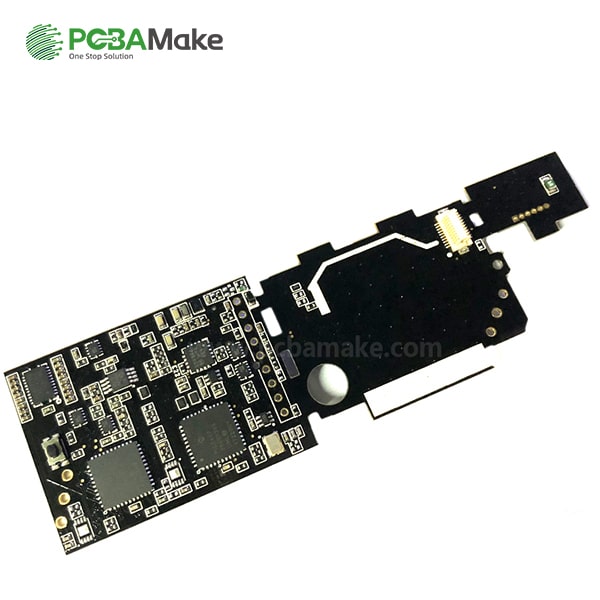

A drone is an unmanned aerial vehicle, an aircraft that can fly without a human pilot but can be operated by remote control. The PCB boards used by drones include rigid and flexible PCB boards.

POE provides PCB board manufacturing services for many drone manufacturers. During our manufacturing process, we found that the hardest printed circuit board in drones is a multi-layer HDI PCB board, which has many special Requirements such as laser drilling, buried/blind/interleaved vias, impedance control, 3/3mil trace width/space, selective ENPEIG (electroless nickel electroless palladium gold) and OSP.

UAV & Drone PCBA have high requirements for PCB board manufacturing, which requires advanced equipment and rich experience to control. POE pcb have rich production experience and technical personnel, and use the world's advanced production equipment to easily respond to customer requirements.. More importantly, we provide a one-stop solution, and one-stop service from PCB production to PCBA processing can save customers a lot of turnaround time.

UAV & Drone PCBA application:

1. Surveying / Mapping / GIS

2. Check

3. Science and research

4. Safety

5. Monitoring

6. Search and rescue

7. Unmanned Cargo

8. Aerial video and photography

In addition to civilian use, drones also have many personal toy applications, and UAV & Drone PCBA boards have similarities in the same way. For more information on UAV & Drone PCBA, please contact the company's customer service! telecommunications PCB assembly industry uses a wide variety of PCBs due to the many different types of equipment used in the industry. Some equipment needs to be placed in a stable indoor environment, while some infrastructure must withstand outdoor environments including storms and extreme temperatures.