The difference between ODM, OEM, JDM in the PCB industry

The PCB industry is a comprehensive industry involving multiple areas and industries, including design, manufacturing, testing, sales and other links. We often hear the words ODM \ OEM \ JDM. Some PCB factory will say that we only do OEM, and some say that we can do ODM. So what is OEM and ODM, and what are the differences between these?Let's understand from the concept:1> Original-Primitive2> Equipment-Equipment3> Design-Design4> Manufacturr-Manufacturer5> Brand-Brand6> Joint-participation, unionThe words are understood, and it will be easy to distinguishOEM (ORIGINAL EQUIPMENT Manufactuer) is the abbreviation of primitive equipment manufacturers, refers to the manufacture of products by one company and selling it with the brand of another company.

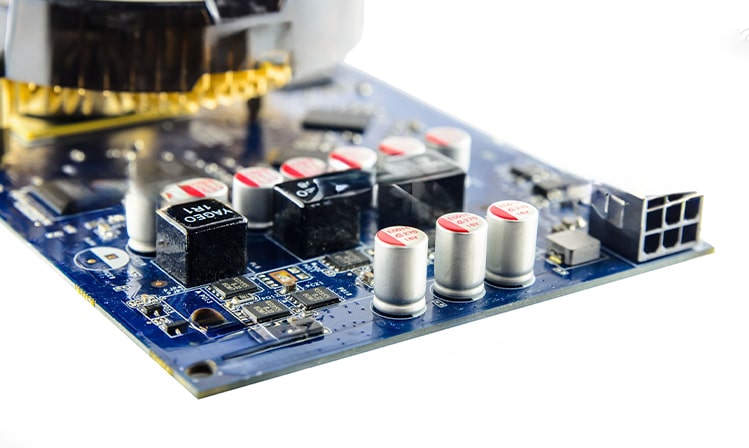

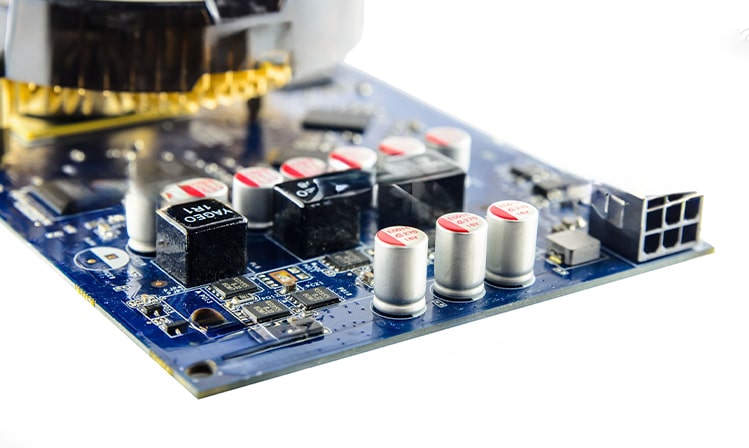

The advantage of the OEM model is that the existing production capacity and equipment can be used to reduce production costs and risks, and improve production efficiency and profit margins.The disadvantage of the OEM model is that it may lose its ability to design and innovate product design and innovation, rely on customers' needs and orders, and facing challenges in price warfare and quality issues.In the PCB industry, the OEM model is usually suitable for some high -customized, high -tech content, high value -added products, such as mobile phone motherboards, automotive electronics, etc.

OEM is also known as foundry manufacturers, authorized OEM production, and fixed -name production.

Simply put: B has a factory building and equipment with large -scale production capacity; A sees B's production capacity, so A first design the product, then send the drawing directly to B, and entrust B to process it according to the drawings, and apply A to A A. The brand, delivered to A.

A possession: equipment

B with: brand, designB undertaking: brand+product designA undertaking: manufacturing

ODM (Original Design Manufactuer) is the abbreviation of the original design manufacturer, which refers to the design and manufacturing of one company, and sells it with the brand of another company.

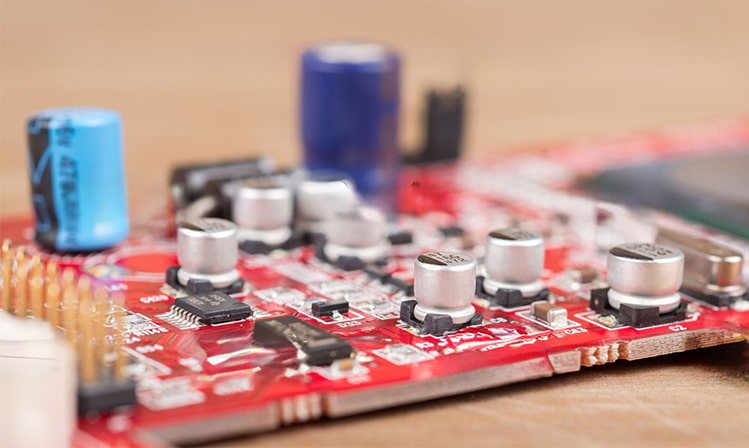

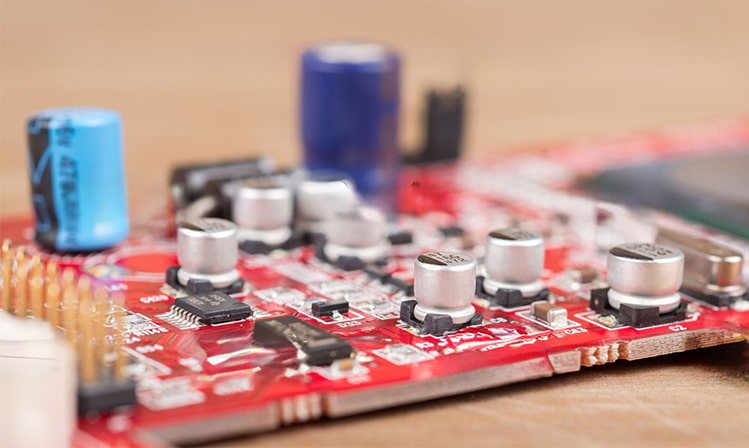

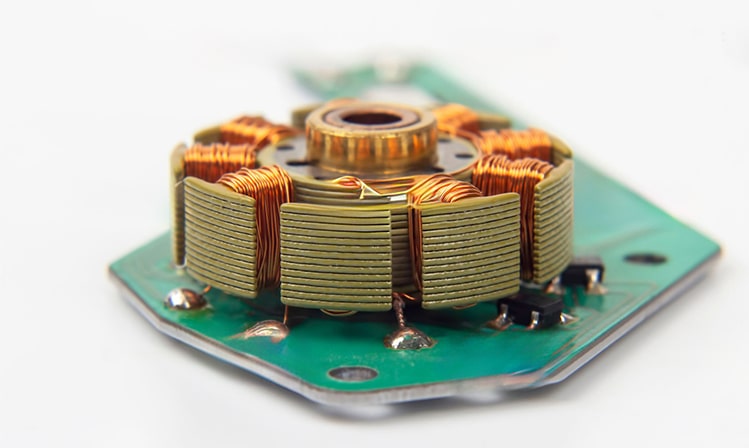

The advantage of the ODM model is that it can reduce R & D costs and risks, shorten product listing time, and improve market competitiveness.The disadvantage of the ODM model is that it may lose independent intellectual property rights, reduce brand value, and face the pressure of homogeneous competition.In the PCB industry, the ODM model is usually suitable for some standardized, generalized, low -tech products, such as power control pcb boards, chargers, etc.

simply put:

A not only has the factory in the factory, but also the development team; the development and design capabilities of A are viewed, so they entrust all the products to the development and production to A; B saves the time of design and research and development.

A with: design development, equipmentB with: brand, designB undertaking: brand; A undertaking: design+manufacturing

JDM (JOINT Design Manufactuer) is a combined design manufacturer's abbreviation, which refers to the design and manufacturing of the product by two or more companies, and sells for the brands of one or more companies.

The advantage of the JDM model is that it can make full use of the resources and advantages of all parties, realize technical exchanges and innovation, improve product quality and performance, and expand market share and influence.

The disadvantage of the JDM model is that it may increase communication and coordination and management costs, conflict with conflicts and trust, and affect the effects and continuity of cooperation.

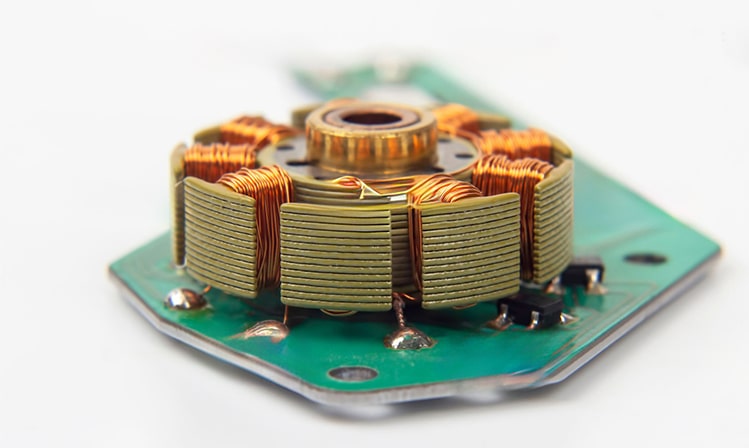

In the PCB industry, the JDM model is usually suitable for some emerging areas, high -end markets, and high difficulty projects, such as smart wearables and medical PCB equipment.

The JDM PCB model is recently proposed by the wave of server manufacturers. It is a new business model that is different from OEM and ODM, that is, for application, integrate the industrial chain, and cooperate with the customer established. The research and development of products has been promoted to more industry customers, from scene satisfaction to trend leadership, and achieves successful business models from short -term products to long -term business models.

for example:

Bank (B) requires a batch of self -service tellers. The teller machine contains the contents of the hardware and software. At this time, they will find a manufacturer with hardware design and manufacturing capabilities (A) to jointly develop this product. In the process, A is biased towards the design and manufacturing of hardware, and B is biased towards the development of software systems.

A with: brand, software developmentB with: hardware development, hardware production manufacturingB undertook the brand, software; A undertakes hardware design+manufacturing, and finally assembles the finished product in the A factory, copys into the software system, pastes A brand, and ships to A.

Pcbamake as a PCB company has developed to a well-known Tum-Key PCB assembly company overthe years, providing high and low volume batches at reasonable prices and high quality, from making the boards to shipping the final productand everything in between.