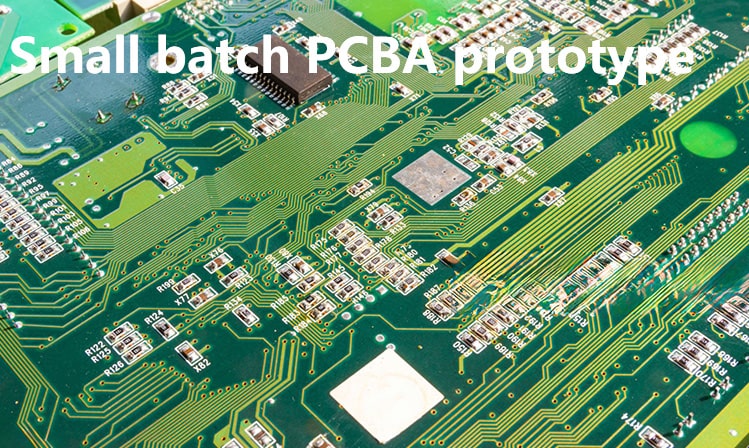

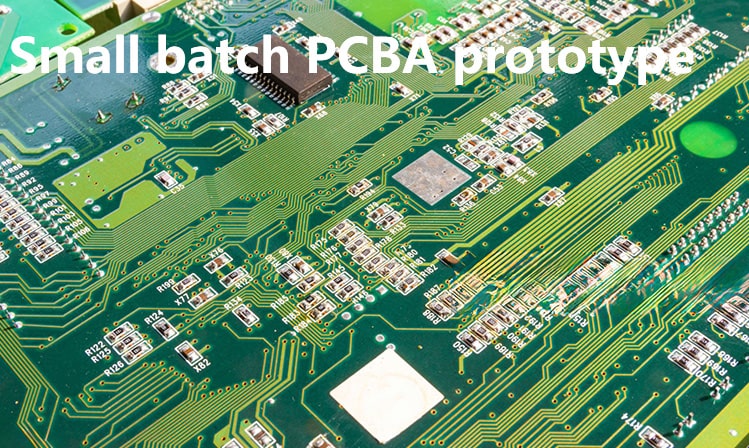

Key Considerations for Small-Batch PCBA Prototyping

In the highly competitive electronics industry, bringing products to market quickly is crucial. Small-batch PCBA prototyping, as a critical phase in product development and testing, directly impacts the success rate of subsequent mass production. For experienced professionals in the PCB industry, understanding the key considerations for small-batch PCBA prototyping is particularly important.

Define Requirements and Communicate Precisely

Clear Project Documentation: Provide detailed project documentation, including a complete BOM list, Gerber files, assembly drawings, and testing requirements, to ensure the supplier accurately understands your needs.

Special Process Specifications: If special processes such as impedance control, blind/buried vias, or immersion gold are required, communicate these in advance to confirm the supplier’s capabilities.

Define Lead Times and Budget: Small-batch prototyping often requires tight deadlines. Clearly communicate timelines and budget constraints with the supplier to avoid future disputes.

Choose the Right Supplier

Experienced PCBA Manufacturer: Select a manufacturer with extensive experience in small-batch PCBA prototyping and familiarity with standards and requirements in the target market (e.g., Europe and North America).

Comprehensive Quality Control System: Ensure the supplier has a robust quality control system, such as ISO9001 certification, and can provide corresponding inspection reports.

Responsive Service Team: Issues may arise during prototyping. Choose a supplier with a responsive service team to promptly address problems and ensure project progress.

Focus on Key Points During Prototyping

Component Sourcing: Ensure components are sourced from reliable suppliers to avoid counterfeit or substandard parts that could compromise quality.

PCB Manufacturing: Pay attention to key parameters such as PCB material, trace width/spacing, and vias to ensure the PCB meets design specifications.

SMT Assembly: Use high-precision SMT equipment to ensure proper soldering and avoid issues like cold joints or short circuits.

Testing and Validation: Conduct comprehensive functional testing and reliability verification to ensure the PCBA performs as expected.

Build Long-Term Partnerships

Continuously Optimize Prototyping Processes: Maintain open communication with the supplier to refine prototyping processes, improving efficiency and quality.

Accumulate Experience and Data: Document lessons learned and data from each prototyping project to inform future mass production.

Establish Trust-Based Relationships: Build long-term partnerships with reliable suppliers to safeguard your projects.

Small batch PCBA prototype is a critical step toward product success. By defining requirements, selecting the right supplier, focusing on key prototyping considerations, and building long-term partnerships, you can effectively reduce risks, improve efficiency, and lay a solid foundation for your product’s successful market launch.

We specialize in providing high-quality small-batch PCBA prototyping services, backed by extensive experience and a robust quality control system. Contact us today to learn more!