How to Choose? Differences and Applications of SMD and Through-Hole Components

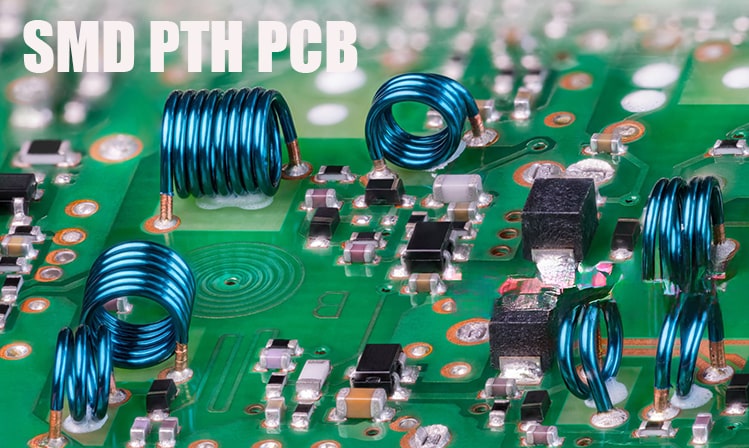

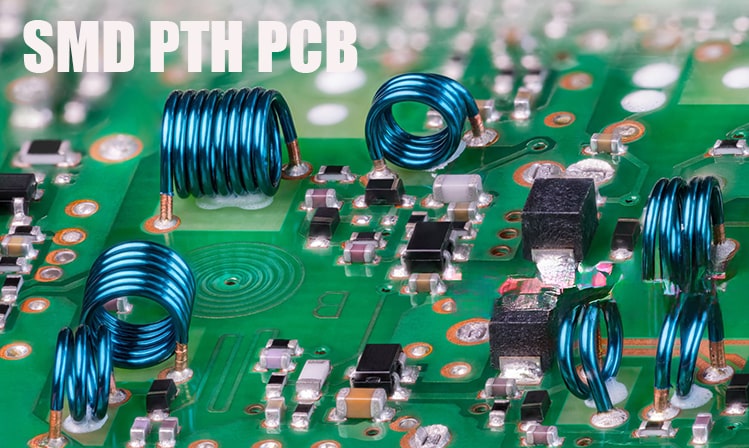

In the field of electronics manufacturing, SMT (Surface Mount Technology) has become the mainstream, involving two main types of components: SMD (Surface Mount Device) and through-hole components. These two types differ significantly in structure, performance, and application scenarios.

SMD Components

SMD components are small, lightweight, and directly soldered onto the surface of PCBs, offering excellent shock resistance. They provide stable soldering quality with low defect rates, enhancing the reliability of electronic products. However, SMD components require advanced production equipment and strict quality control.

They are widely used in small, high-density, and highly integrated electronic devices, such as smartphones, computers, and tablets. These consumer electronics demand compact size, lightweight design, and high performance, making SMD components the preferred choice.

Through-Hole Components

Through-hole components have pins inserted into PCB holes, providing strong mechanical stability. They are often used in power devices with high heat dissipation requirements, offering superior performance and long-term stability compared to SMD components. However, through-hole components have lower shock resistance and may face issues like pin deformation or poor hole alignment during production.

They are more suitable for larger and heavier components, such as power modules and relays, commonly used in industrial control and medical equipment, where stability and reliability are critical.

SMD and through-hole components differ significantly in structure, performance, and application scenarios. When selecting components, it is essential to consider the specific product requirements and circuit design to ensure optimal performance and reliability.

PCBAMake specializes in PCB fabrication, SMT assembly, and component sourcing, offering end-to-end solutions from material selection to prototyping, small-batch production, and testing. Equipped with advanced machinery, including 3 brand-new Korean imported (Samsung) dual-track medium and high-speed placement machines,, automated printers, reflow ovens, inline AOI/SPI, offline AOI, and X-RAY, we are dedicated to providing R&D-focused enterprises with efficient, high-quality, one-stop PCBA services.