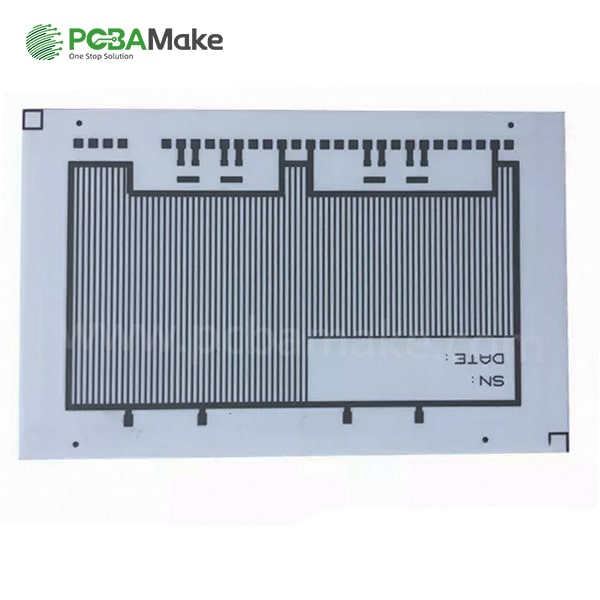

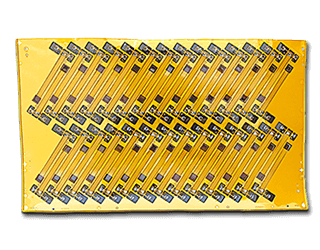

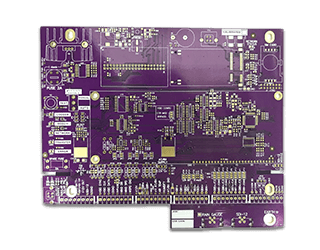

Ceramic PCB

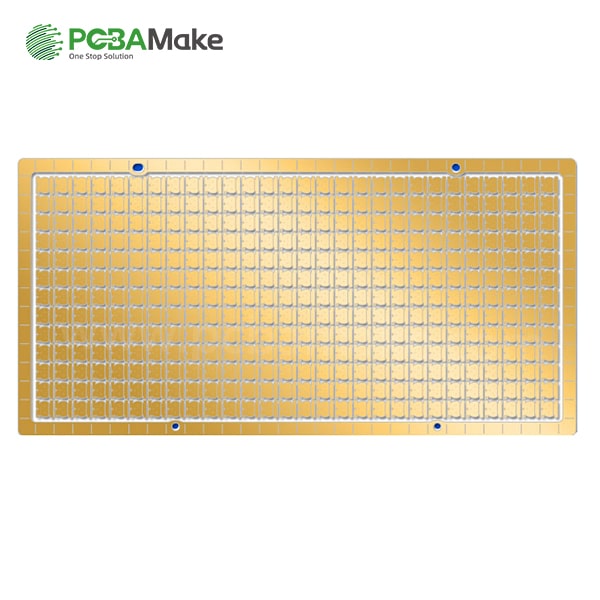

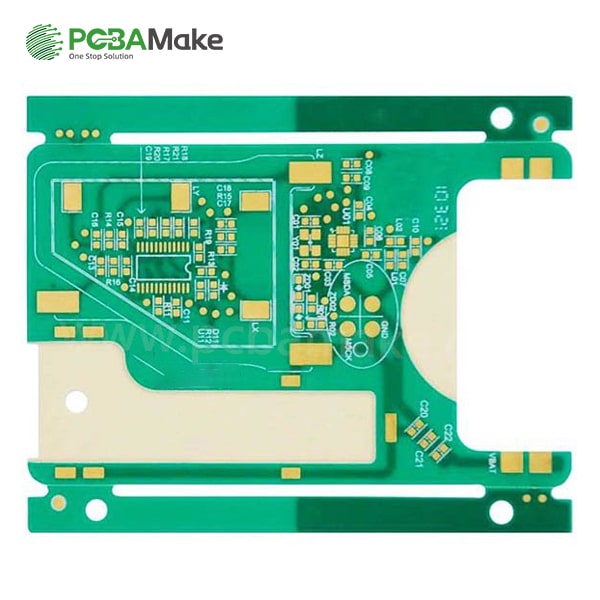

With continued demands for miniaturization, microelectronics, and high-power LED packaging, substrates that can withstand high operating temperatures while providing excellent thermal performance are required. Ceramic PCBs have become a more viable option for PCB designers.

Ceramics have been widely used in electronic/electronic components for many years due to their advantages in thermal and mechanical properties. Since its introduction, ceramic PCBs have received great attention from the industry as an effective solution to a range of electronic problems.

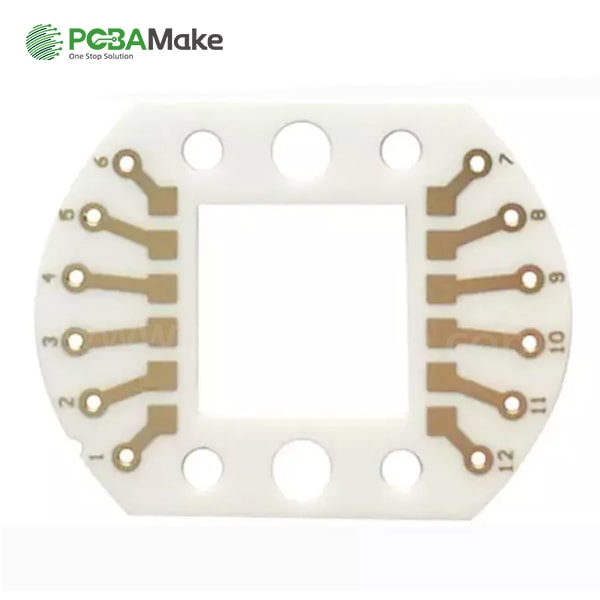

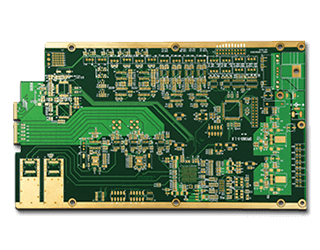

Advantages of ceramic pcb compared to other technologies

Heat dissipation is a key advantage of ceramics over traditional materials such as FR4 and metal-clad PCBs. Since the components are placed directly on the board and there are no isolation layers, the heat flow through the board is much more efficient.

In addition to this, ceramic materials can withstand high operating temperatures (up to 500°C) and have an extremely low coefficient of thermal expansion (CTE), providing additional compatibility options for circuit designs.

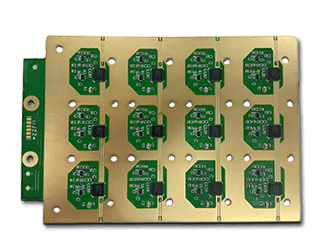

Ceramic pcb advantage performance parameters

Excellent thermal conductivity (up to 170W/mK)

Operating temperature up to 500°C

Low thermal expansion coefficient

Suitable for high frequency applications due to low signal loss

The water absorption rate is 0%, and it is sealed and packaged with good air tightness.