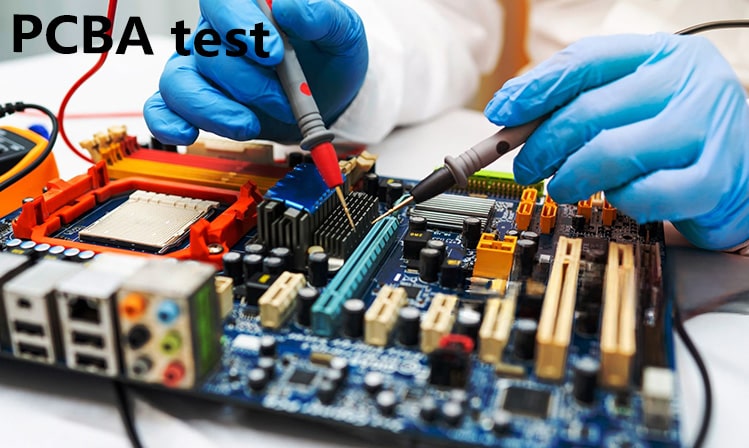

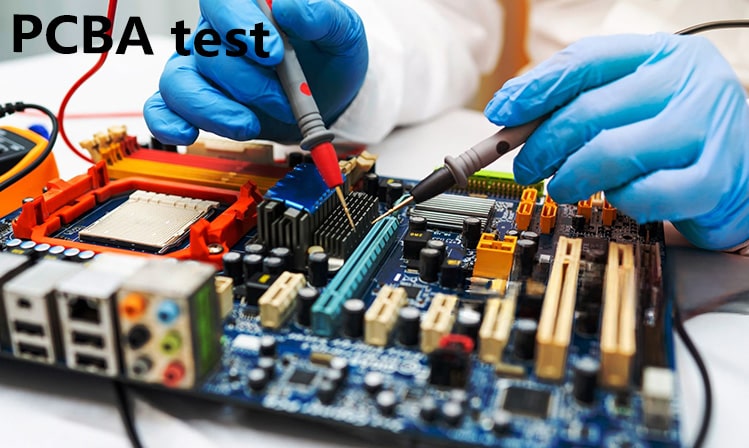

PCBA Test Fixtures: Ensuring Quality and Reliability in Electronics Manufacturing

In the fast-paced world of electronics manufacturing, ensuring the quality and reliability of Printed Circuit Board Assemblies (PCBAs) is paramount. This is where PCBA test fixtures come into play, serving as indispensable tools for verifying the functionality and performance of assembled boards.

Understanding the Basics: PCB vs. PCBA

Before delving into test fixtures, it's crucial to differentiate between a PCB and a PCBA:

PCB (Printed Circuit Board): The physical board comprising insulating material and conductive pathways that connect electronic components.

PCBA (Printed Circuit Board Assembly): A PCB populated with electronic components like resistors, capacitors, integrated circuits, etc., forming a functional electronic circuit.

The Role of PCBA Test Fixtures

PCBA test fixtures are specialized devices designed to interface with a PCBA, enabling comprehensive electrical testing. They serve as a bridge between the PCBA and automated test equipment (ATE), facilitating:

Continuity Testing: Verifying the integrity of electrical connections and identifying open or short circuits.

Component Verification: Ensuring the correct placement, orientation, and functionality of individual components.

Functional Testing: Simulating real-world operating conditions to validate the overall performance of the PCBA.

In-Circuit Testing (ICT): Assessing the electrical characteristics of individual components while they are soldered onto the PCB.

Benefits of Utilizing PCBA Test Fixtures

Incorporating PCBA test fixtures into your manufacturing process offers a multitude of advantages:

Enhanced Quality Control: Early detection and rectification of defects minimize the risk of faulty products reaching the market.

Increased Production Efficiency: Automated testing significantly reduces testing time and labor costs compared to manual methods.

Improved Product Reliability: Thorough testing ensures consistent performance and longevity of electronic devices.

Reduced Time-to-Market: Streamlined testing processes accelerate product development cycles.

Choosing the Right PCBA Test FixtureSelecting the appropriate test fixture depends on various factors, including:

PCBA Complexity: The number of components, board size, and type of connectors influence fixture design.

Testing Requirements: The specific tests to be performed (e.g., functional, in-circuit) dictate the fixture's capabilities.

Production Volume: High-volume production may necessitate automated fixtures, while low-volume runs might utilize manual or semi-automated options.

Partnering with a Reliable PCBA Manufacturer

At PCBAMake, we understand the critical role PCBA test fixtures play in delivering high-quality electronic products. Our state-of-the-art facilities are equipped with advanced test fixtures and operated by skilled technicians, ensuring the reliability and functionality of every PCBA we produce.

Contact us today to learn more about our comprehensive PCBA manufacturing and testing services. We are committed to being your trusted partner in bringing your electronic innovations to life.