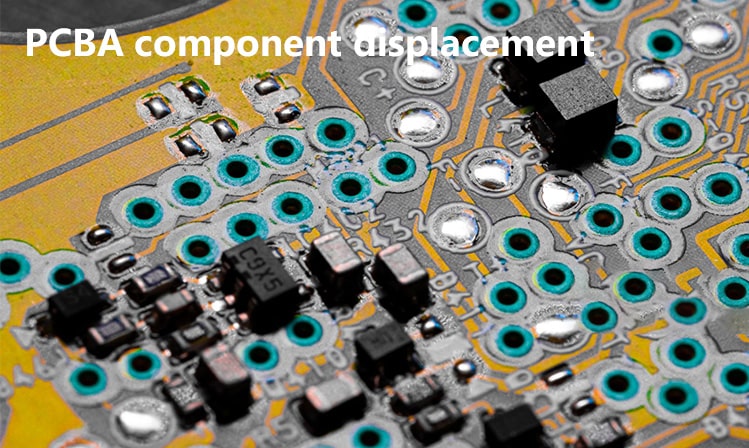

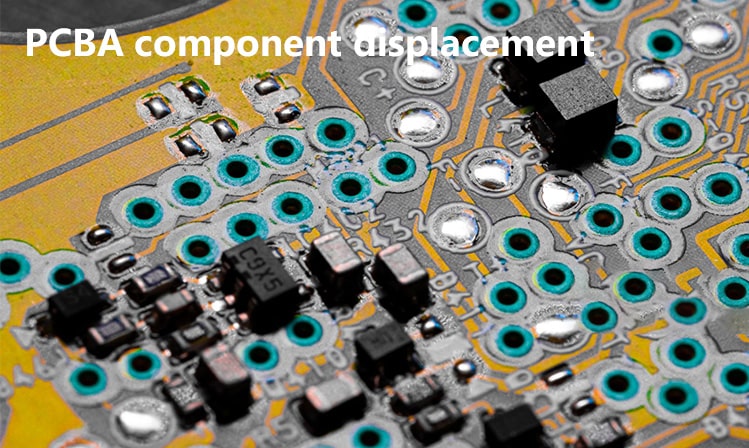

Why Do Components Shift During SMT Assembly?

If you’ve ever wondered why components on a printed circuit board (PCB) sometimes shift during Surface Mount Technology (SMT) assembly, you’re not alone. This common issue can affect the quality and functionality of your PCB, leading to delays and added costs. In this article, we’ll break down the reasons behind component shifting in SMT assembly and how to prevent it, ensuring your PCBs are built to the highest standards.

What is SMT Assembly?

Surface Mount Technology (SMT) is a method used to place electronic components directly onto the surface of a PCB. It’s a highly efficient process that allows for smaller, faster, and more reliable electronic devices. However, even with advanced machinery, issues like component shifting can occur during assembly.

Common Causes of Component Shifting in SMT Assembly

Incorrect Solder Paste Application

Solder paste is used to temporarily hold components in place before they are permanently soldered. If too much or too little solder paste is applied, components may not adhere properly and can shift during the reflow process. Uneven application can also cause components to tilt or move.

Improper Reflow Oven Settings

The reflow oven is where the solder paste melts and solidifies, bonding the components to the PCB. If the temperature profile is not optimized, it can cause uneven heating, leading to components shifting as the solder melts and reflows.

Vibration or Movement During Conveyor Transport

PCBs move through the assembly line on a conveyor belt. If the conveyor vibrates or moves too quickly, it can cause components to shift before the solder paste solidifies.

Incorrect Component Placement

Even with automated pick-and-place machines, misalignment can occur if the machine is not calibrated correctly or if the components are not fed properly into the machine.

PCB Design Issues

Poor PCB design, such as uneven pad sizes or inadequate spacing between components, can make it difficult for components to stay in place during assembly.

Environmental Factors

Humidity, temperature fluctuations, and static electricity in the manufacturing environment can also contribute to component shifting.

How to Prevent Component Shifting

Optimize Solder Paste Application

Ensure the solder paste is applied evenly and in the right amount. Stencils should be regularly cleaned and inspected to avoid clogging or misalignment.

Refine Reflow Oven Settings

Work with your manufacturer to establish the optimal temperature profile for your specific PCB design. This will ensure even heating and proper solder reflow.

Stabilize Conveyor Systems

Minimize vibrations and ensure the conveyor speed is appropriate for the assembly process. Regular maintenance of the conveyor system is essential.

Calibrate Pick-and-Place Machines

Regularly check and calibrate the pick-and-place machines to ensure accurate component placement. Proper feeder setup is also critical.

Review PCB Design

Collaborate with your design team to ensure the PCB layout is optimized for SMT assembly. Pay attention to pad sizes, component spacing, and thermal considerations.

Control the Manufacturing Environment

Maintain a stable environment with controlled humidity and temperature. Use anti-static measures to prevent static discharge, which can affect component placement.

Why Choose Us for Your SMT Assembly Needs?

At PCBAMake, we specialize in high-quality SMT assembly for clients across the globe. Our state-of-the-art facilities, experienced engineers, and rigorous quality control processes ensure that your PCBs are built to perfection. We understand the challenges of component shifting and take every precaution to deliver flawless results.

Whether you’re a startup or an established business, we’re here to provide reliable, cost-effective PCB solutions tailored to your needs. Contact us today to learn more about our services and how we can help you achieve your electronic manufacturing goals.

By understanding the causes of component shifting and working with a trusted manufacturer, you can ensure your PCBs are built to the highest standards. Let us help you bring your electronic designs to life with precision and reliability.