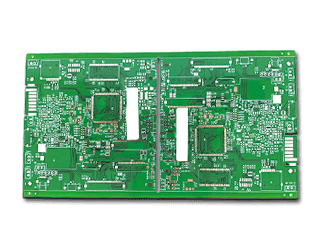

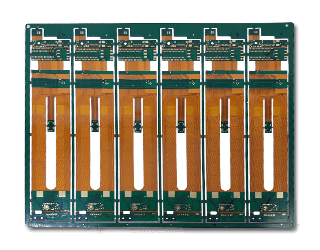

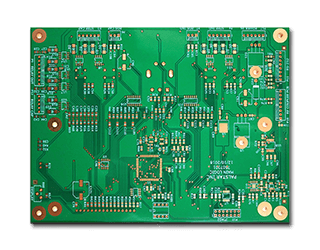

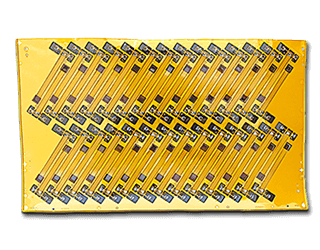

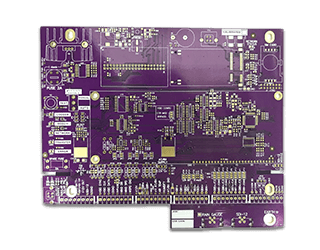

LED PCB

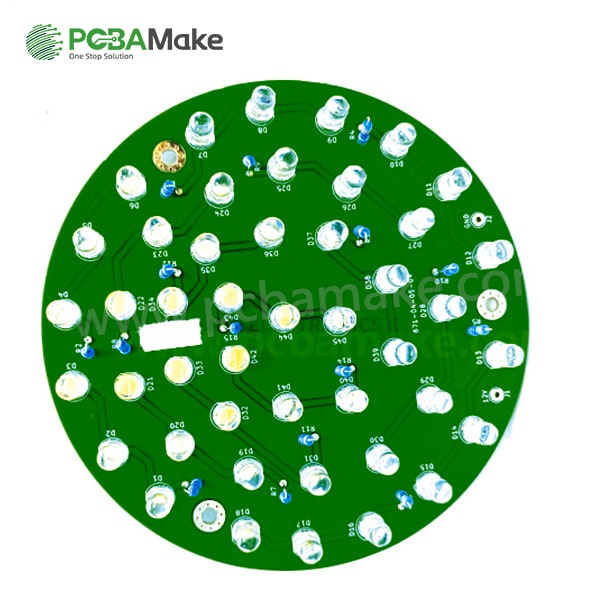

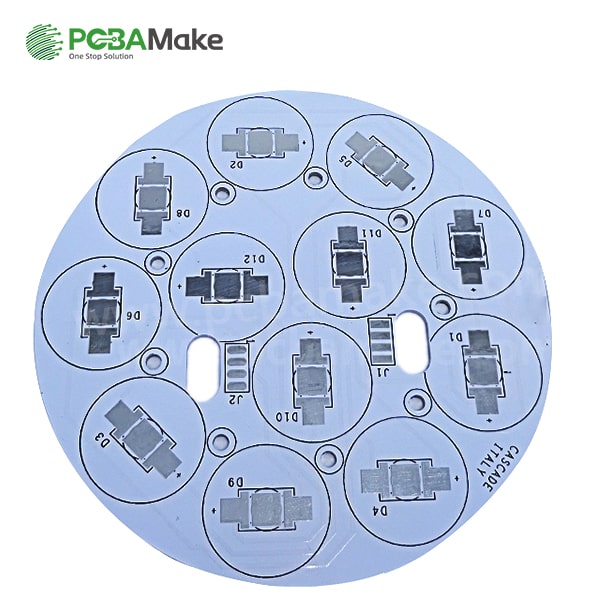

LED PCB board technology has developed into the innovation of many new products. A good example is the development of PCBs for LED lighting. The LEDs are soldered to the circuit board, and the chips produce light when electrically connected. Heat sinks and ceramic bases are used to attach the chips to absorb heat and cool the process.

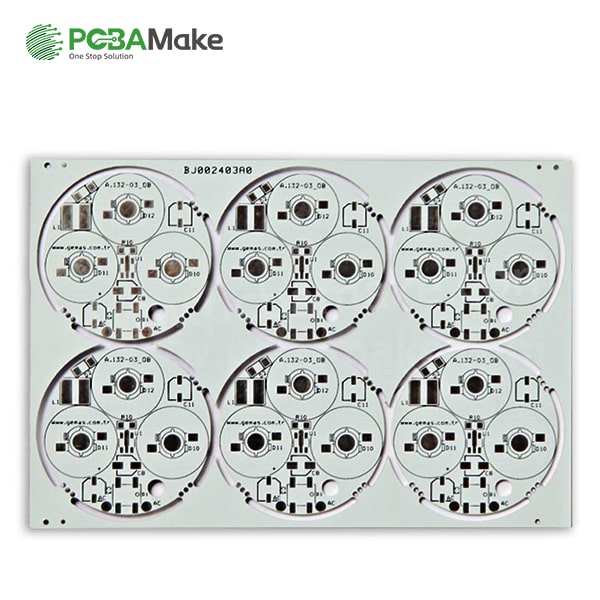

LED PCB panels tend to induce a lot of heat, which makes cooling by conventional means laborious. Therefore, LED circuit boards are usually selected to improve the heat dissipation capability of the LEDs. In particular, aluminum is often used to produce circuit boards for LED lamps. Aluminum PCBs typically include a thin layer of thermally conductive dielectric material that relocates and dissolves heat with superior coherence compared to unyielding PCBs.

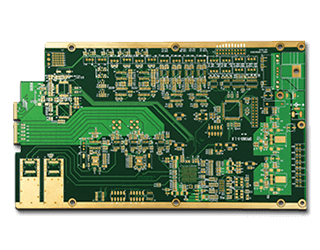

LED PCB Application

LED PCB luminaires can be integrated into many lighting applications due to their excellent energy efficiency, low cost and maximum design flexibility, such as: traffic lights, car headlights, military lighting, street tunnel lighting, airport runways, street lighting , photovoltaic (solar) lighting, flashlights and lanterns, hospital operating room lighting, factory lighting, and more.

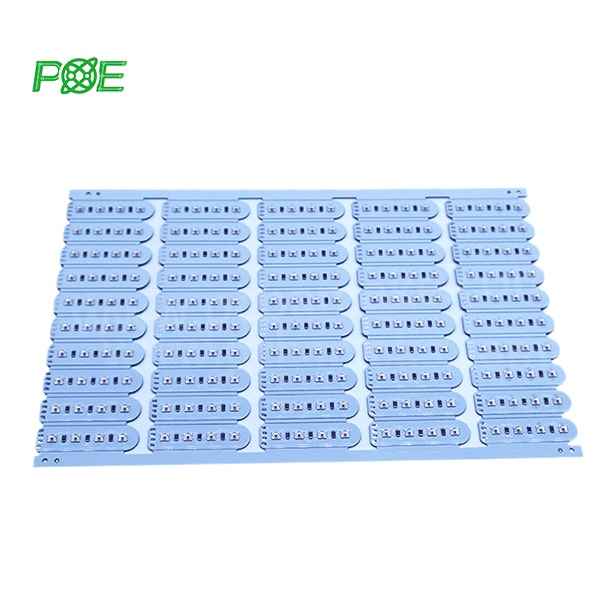

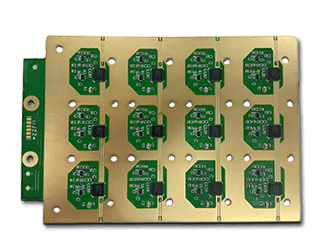

POE PCB has state-of-the-art facilities and a very enthusiastic design team waiting for your queries and PCB design requests. If you want a specific application, such as outdoor lighting or LED screens, you can always come to our design team and we will come up with a solution that is perfectly suitable for you.