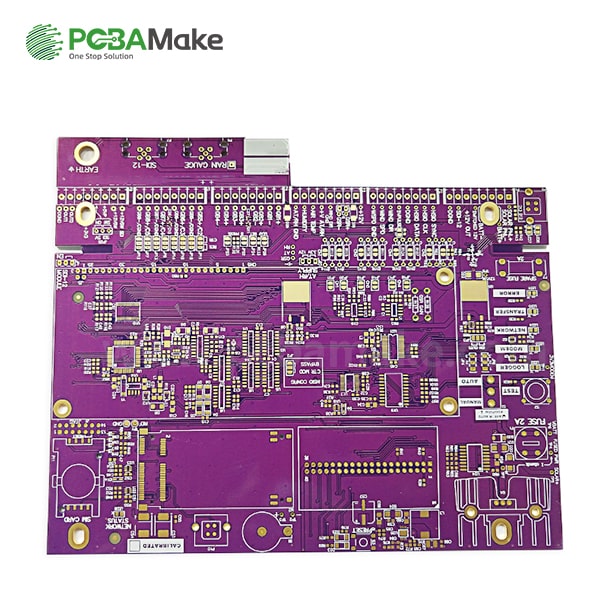

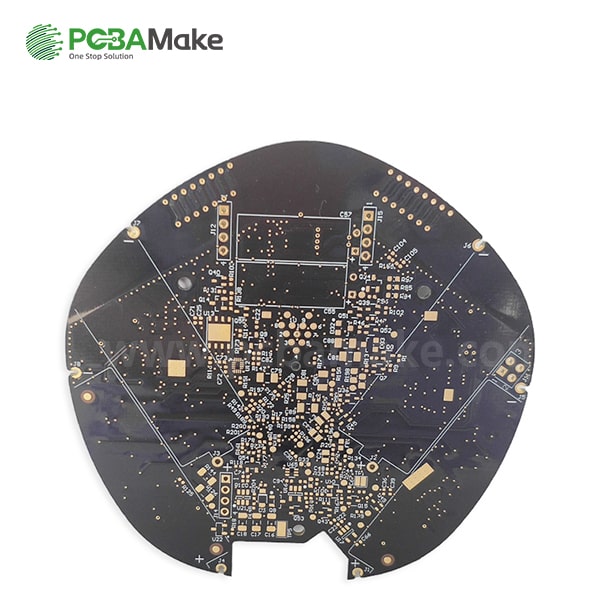

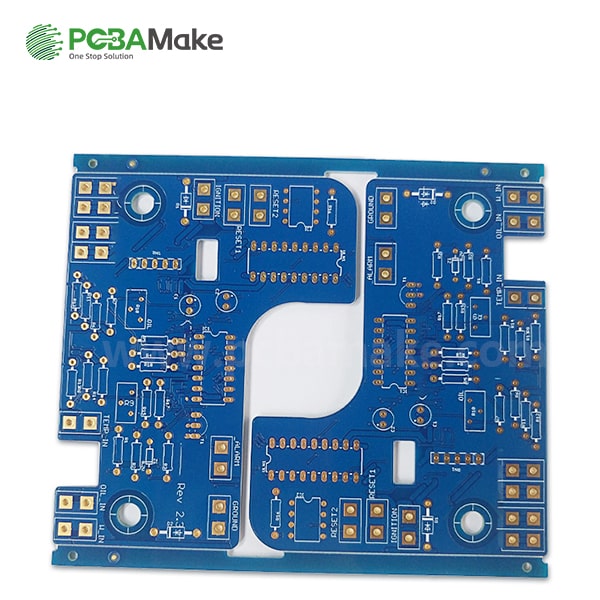

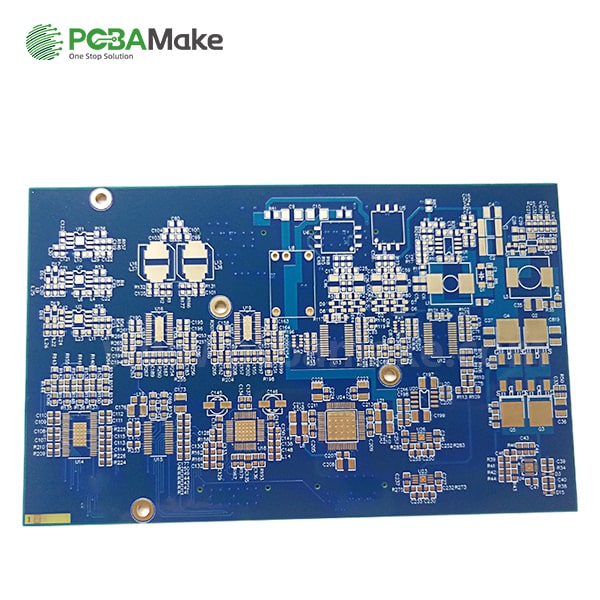

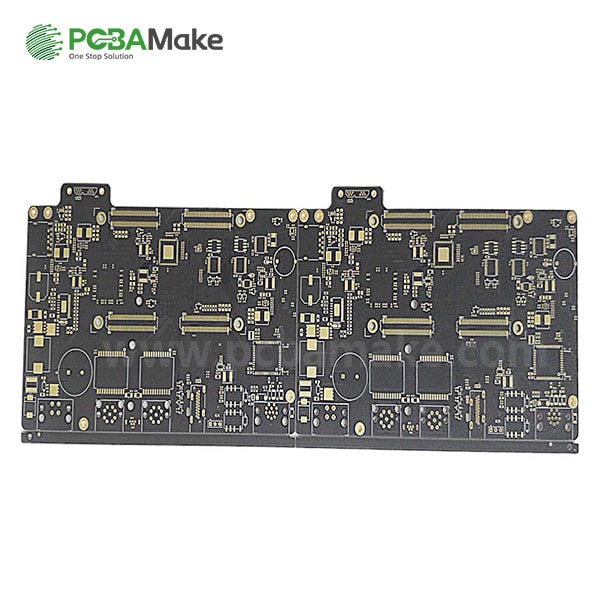

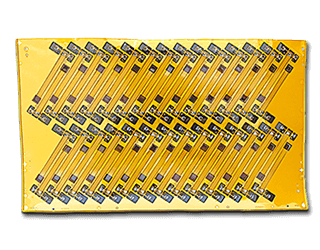

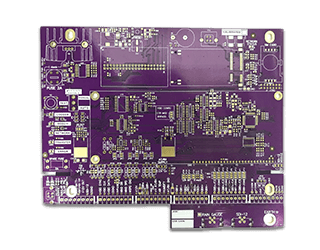

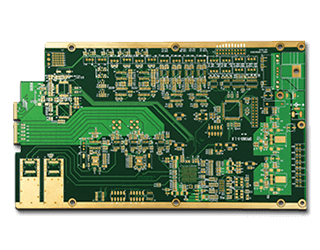

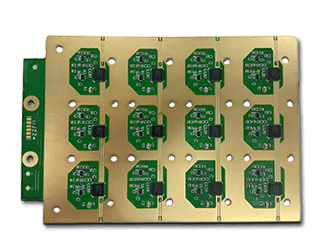

Thick copper PCB

The thick copper PCB plate is a layer of copper foil bonded on the glass epoxy substrate of the PCB. When the copper thickness is greater than or equal to 2oz, it is defined as a thick copper PCB.

Thick copper PCB plate has the best elongation performance and is not limited by processing temperature. It can be welded with oxygen blowing at high melting point, and it is not brittle at low temperature. It is also fireproof and belongs to non-combustible material. Copper plates form a strong, non-toxic passivation protective layer even in extremely corrosive atmospheres.

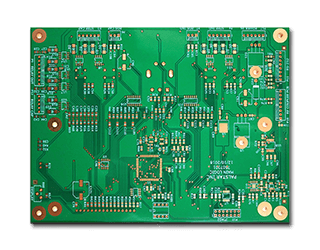

The application of thick copper plates in PCB prototype is almost ubiquitous, and the vast majority of thick copper plates are high-current substrates. The main application areas of high-current substrates are two major areas: power modules and automotive electronic components. Some of its main terminal electronic product fields are the same as conventional PCBs, and some are different from conventional PCB fields, such as automobiles, industrial control, power modules, etc. Thick copper PCB plate has excellent elongation performance, high temperature, low temperature and corrosion resistance, which makes electronic equipment products have a longer service life, and also greatly helps to simplify the volume of electronic equipment. Especially electronic products that need to run higher voltages and currents require thick copper PCB plates.

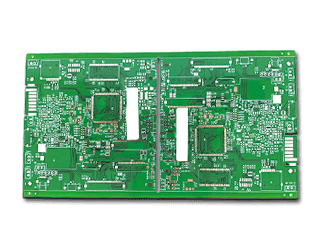

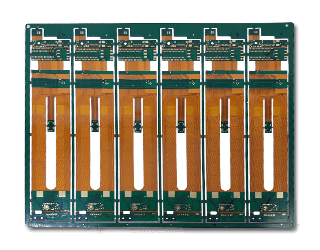

In PCB prototype, thick copper PCB plate is a special process, with certain technical thresholds and operational difficulties, and the cost is relatively expensive. POE is committed to solving the pain points that enterprises have nowhere to process difficult boards, precision boards, and special boards in PCB prototype, and provides customers with thick copper PCB boards, high-end HDI PCBs, rigid-flex PCBs, blind and buried-hole PCB boards, and high-frequency PCBs. and other special process printed circuit boards.