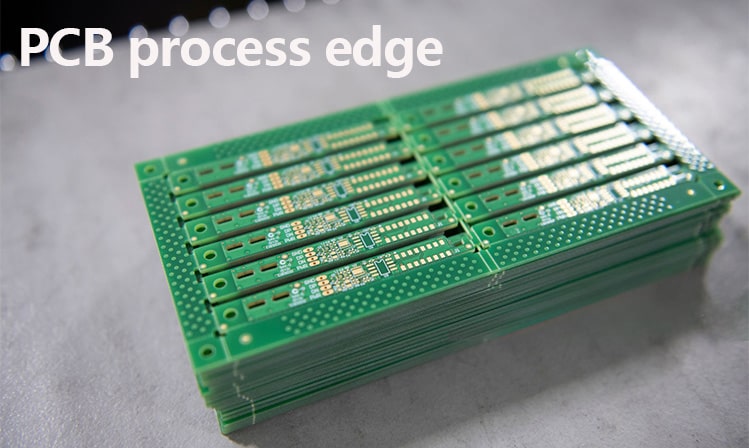

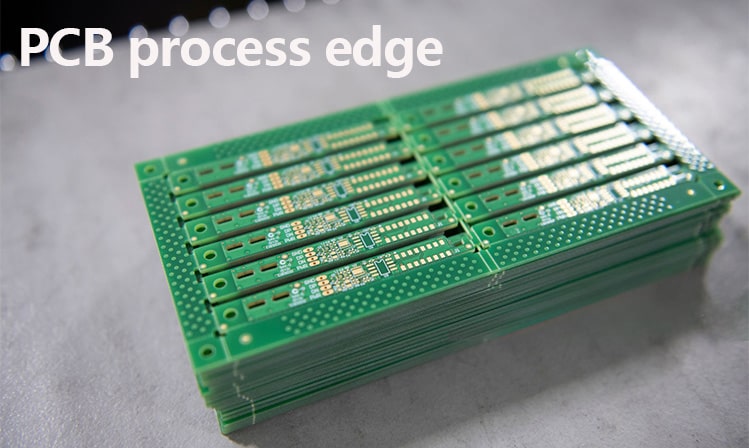

PCB process edge

In the PCB production process, there is one more important process, which is the process edge. The PCB process edge is very important in the production process. It is mainly used to assist the patch plug-in welding board and prevent the SMT placement machine nozzle from sucking. Collision occurs when components are used.

PCB process edge manufacturing methods include V-CUT and connecting ribs. The design requires economy and manufacturability to be considered. Specially shaped PCB boards need to be cleverly simplified through panelization.

The role of PCB process edges

The process edge is the part added on both sides or four sides of the PCB board. It is mainly used to assist the welding process of the patch plug-in, that is, it is convenient for the SMT placement machine track to clamp the PCB board and flow through the placement machine. If the element is too close to the track edge, When the components are picked up by the nozzle of the SMT placement machine and mounted on the PCB board, collisions may occur, resulting in inability to complete production. Therefore, a certain process edge must be reserved, generally with a width of 2-5mm, etc. This method is also suitable for some plug-in components to prevent similar phenomena during wave soldering.

The process edge is not part of the PCB board and can be removed after the PCBA manufacturing is completed.

How to make PCB process edges

1. V-CUT: A process connection between the process edge and the board. Cut slightly on both sides of the PCB board, but do not cut it!

2. Connecting ribs: Use several ribs to connect the PCB boards, and punch some stamp holes in the middle so that they can be broken by hand or washed with a machine.

Design requirements for PCB process edges

Not all PCB boards need to add process edges. If the space on the PCB board is large, leave no chip components within 5mm on both sides of the PCB. In this case, there is no need to add process edges. There is another way. The situation is that there are no SMD components within 5mm on one side of the PCB board. It is enough to add a process edge on the other side. These require the attention of PCB engineers.

The boards consumed by the process side will increase the overall cost of the PCB. Therefore, when designing the PCB process side, it is necessary to balance economy and manufacturability.

For some special-shaped PCB boards, the original PCB board with 2 or 4 process edges can be greatly simplified by cleverly combining panels.

The Importance of PCB Processing Edge

PCB processing technology plays a very important role in electronic equipment, which is mainly reflected in the following aspects.

Efficiently control board size and shape

During PCB processing, by controlling the width and shape of the process edge, it is possible to ensure that the size of the circuit board is consistent with the design requirements. This is crucial for the proper operation of electronic equipment. If the circuit board size does not meet the requirements, it may cause the electronic components to not be installed correctly, thus affecting the functionality of the entire device.

The role of protecting circuit boards

After additional processing, the process edge can prevent the edges of the circuit board from being exposed to the outside environment, thereby reducing the risk of damage caused by the influence of the outside environment. Electronic equipment is usually used under various harsh conditions, such as high temperature, humidity, etc. If the circuit board does not have suitable process edges, it may be damaged by these factors, causing the overall performance of the equipment to decline or fail.

Improve circuit board strength and stability

Craft edges can increase the mechanical strength of the circuit board, making it more resistant to external shock and vibration. The process edge can also reduce the deformation and warping of circuit boards, ensure the stability and reliability of electronic components, and extend the life of equipment.

PCB processing technology plays a vital role in the manufacturing of electronic equipment.

Mastering and correctly handling relevant knowledge such as the size, shape and design requirements of PCB processing technology edges can ensure that the quality and performance of the circuit board meet the requirements. Therefore, for any company or individual engaged in electronic equipment manufacturing, it is indispensable to understand the role and importance of PCB processing edges.

As a company with extensive experience in the PCB processing industry, PCBAMake knows the importance of process edges. We are committed to providing customers with high-quality PCB processing services and ensuring precise control and reasonable design of process edges. Our professional team will ensure that the process edges of each PCB board meet standards and provide quality solutions and support based on customer needs and requirements.