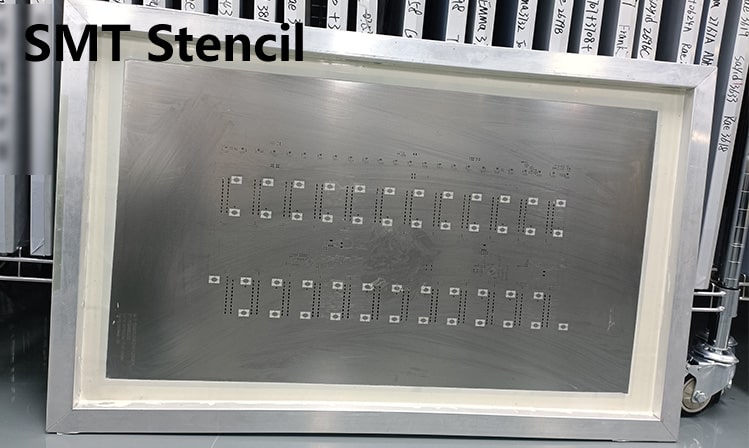

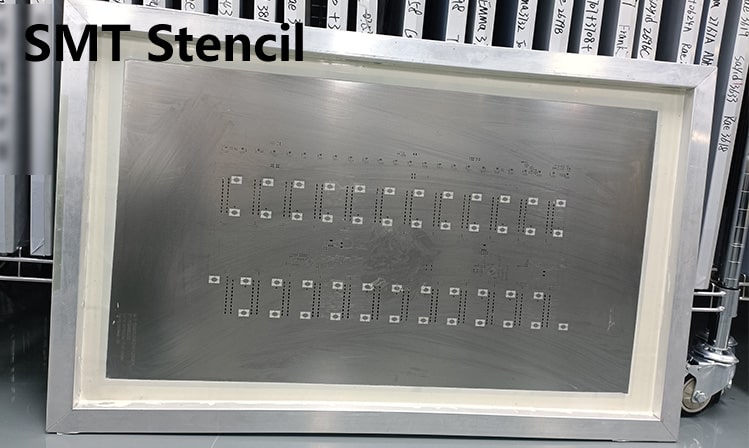

What types of SMT stencils are there?

In surface mount technology (SMT), stencils are key tools used to precisely deposit solder paste onto circuit boards.

There are mainly the following types of SMT stencils:

Laser stencils

This is one of the most commonly used stencil types in SMT patch processing. Laser stencils are made directly using data files and are made by laser-precision cutting of stainless steel plates. The opening accuracy is high and the edges are smooth. The error links in the production process are reduced, and it is suitable for products with high precision requirements, such as fine pitch components. Compared with chemically etched stencils, laser-cut stencils have higher opening accuracy and edge quality.

Electropolished stencils

This type of stencil is made by post-processing the steel sheet by electrochemical methods after laser cutting to improve the surface quality of the opening hole wall and make the hole wall smoother, which is particularly suitable for ultra-fine pitch QFN/BGA component welding.

Chemically etched stencils

Opening holes are etched on metal plates through a chemical corrosion process. The production cost is low. It is suitable for products with low precision requirements. This type can be considered for mass-produced and cost-sensitive projects. Compared with laser-cut steel mesh, chemically etched steel mesh has poor opening accuracy and edge quality.

Step steel mesh

The step steel mesh is designed according to the different requirements for the amount of solder paste when soldering various components on the same PCB. By locally thinning the steel mesh, the soldering requirements of different components are met and the amount of tin when soldering specific components is reduced.

Etched steel mesh

It is suitable for printing PCB boards with corners and spacing greater than or equal to 0.4MM, and is suitable for occasions where copy boards and films are required. Etched steel mesh is relatively quick to make, and the price is cheaper than laser steel mesh, which is convenient for customers to archive and use.

These different types of steel meshes have their own characteristics and applicable scenarios. Choosing the right type of steel mesh is crucial to ensuring the quality and efficiency of SMT patch processing.