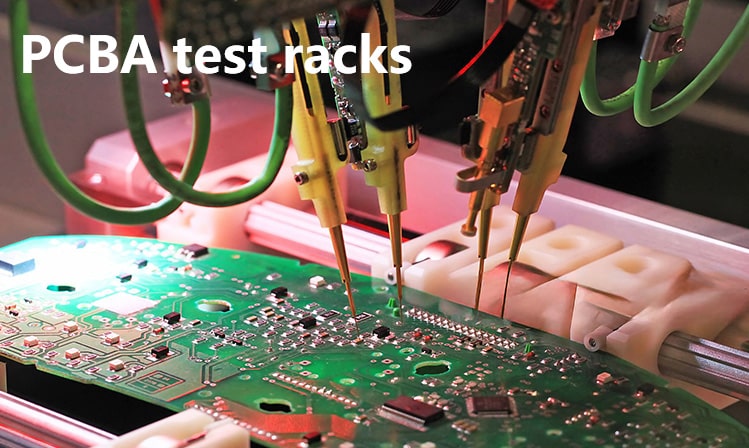

Principle and purpose of PCB and PCBA test racks

PCBA test racks are important tools to ensure the quality and reliability of circuit boards

1. Design and customization of test racksThe design of PCBA test racks is based on the specific needs of circuit boards, and it needs to be precisely connected to the test points of the circuit board under test. During the design process, engineers will analyze the functional requirements of the circuit board in detail to ensure that the test rack can cover all key test points and signal paths. This tailored approach enables the test rack to efficiently and accurately perform fault detection and functional verification, and ensure the quality of each circuit board.

2. Early diagnosis and prevention of faults

PCBA test racks can detect some potential problems in the early stages of production, such as defective components and welding errors, which makes early diagnosis and prevention possible. By promptly discovering and repairing these problems, not only can defective products be prevented from flowing into the next production link, but also costs and time can be greatly reduced. In addition, the detailed fault data provided by the test rack helps the manufacturing team analyze the cause of the fault, thereby optimizing the production process and improving the overall production quality.

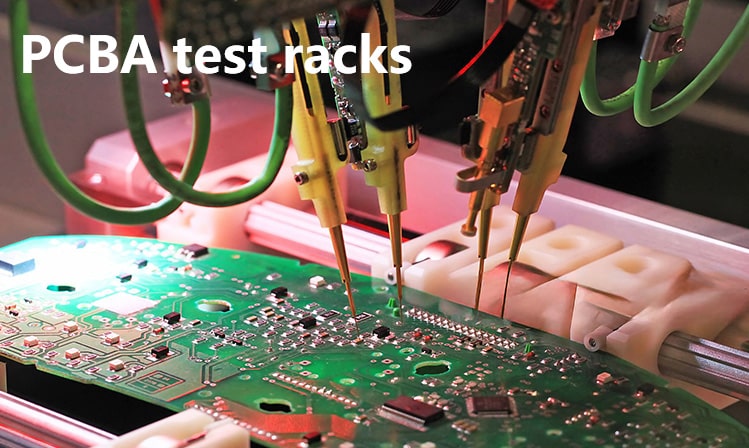

3. Automated testing improves production efficiency

The automated testing function of the PCBA test rack greatly improves production efficiency. Traditional manual testing is not only time-consuming and labor-intensive, but also prone to test errors due to improper operation. Automated test racks can perform rapid and continuous testing, with precise repetition, ensuring that each PCBA board is tested to the same standard, minimizing the impact of human factors on test results.

4. Product consistency and reliability assurance

In large-scale production, it is essential to maintain product consistency and reliability. PCBA test racks ensure that each PCBA board meets uniform quality standards before leaving the factory by executing standardized test procedures. This not only lays a solid foundation for the reliability of the final product, but also greatly enhances consumers' trust in the brand.

5. Flexibility and adaptability

The design of the PCBA test rack is highly flexible and adaptable, and can quickly adapt to the testing needs of different products. Whether it is changing different test procedures or adjusting the fixture to adapt to new PCBA boards, the test rack can be quickly adjusted to meet the quality inspection needs of different products. This adaptability makes the test rack an indispensable quality control tool in the electronics manufacturing industry.

The role of the PCBA test rack in strictly controlling quality cannot be underestimated. Through efficient and accurate testing, early fault detection, and improved production efficiency and product consistency, the test rack provides a reliable quality assurance method for the electronics manufacturing industry. PCBAMake also provides test rack services. We are a one-stop PCB OEM manufacturer that provides PCB manufacturing, component purchasing, patch processing, testing, customized shell packaging, and other global shipments. If you have any PCB or PCBA related needs, please feel free to contact us.