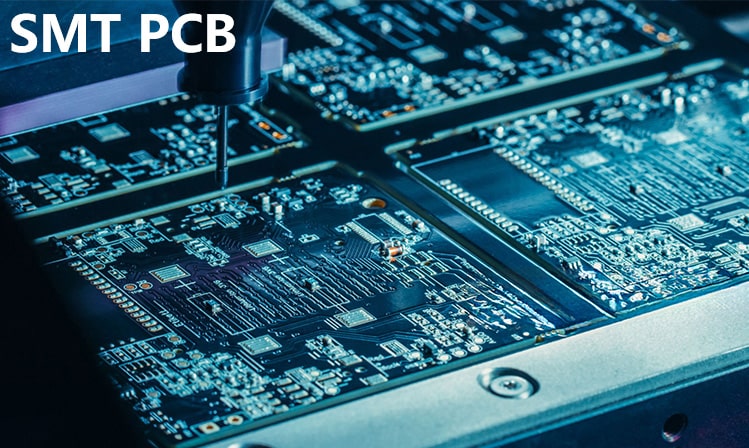

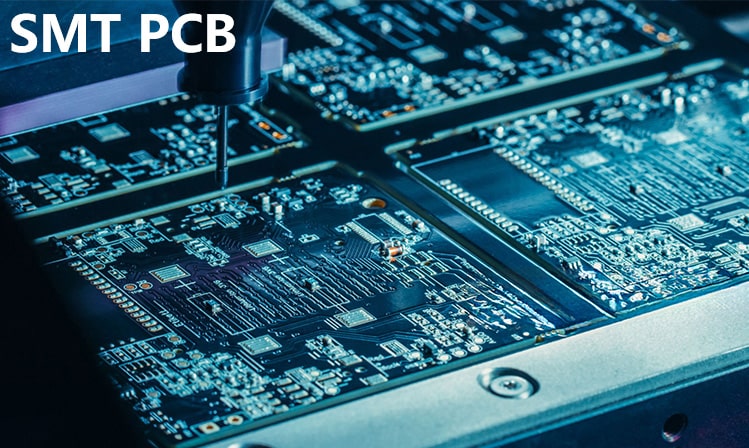

Why should PCB be baked during SMT patch processing?

In the process of SMT (surface mount technology) patch processing, baking of PCB (printed circuit board) is a key step. By baking the PCB, the stability and reliability of the processing can be effectively improved, and a series of potential problems can be avoided.

The role of baking PCB before patch processing

Remove moisture: PCB may absorb moisture from the air during storage and transportation. Humidity may have an adverse effect on electronic components and the welding process. By baking, moisture on the PCB can be effectively removed to ensure that it will not cause poor welding or damage to components during subsequent welding.

Prevent welding bubbles: Moisture in the PCB evaporates at high temperatures. If it is not baked in advance, when the PCB enters the welding process, moisture may form bubbles at high temperatures. These bubbles may cause the solder joints to be loose and affect the reliability of the electrical connection. By pre-baking, the risk of welding bubbles can be reduced.

Improve component adhesion: Baking also helps to improve the adhesion of components on the PCB surface. This is critical for the SMT (Surface Mount Technology) patch process, as components need to be firmly adhered to the PCB surface to ensure reliable connections.

Avoid thermal shock: Thermal shock caused by temperature changes in the PCB may have a negative impact on electronic components. By baking at a controlled temperature before production, thermal shock can be mitigated or avoided, ensuring that electronic components are not damaged throughout the manufacturing process.

In SMT patch processing, baking the PCB is a step that cannot be ignored. It can not only effectively reduce welding defects and improve product quality, but also ensure the long-term reliability of the product. This process provides a solid foundation for manufacturing high-quality electronic products.